Super KB

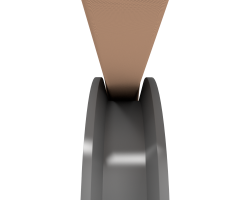

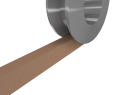

The Super KB belt is very popular when it comes to garden machinery and shredding applications. The coating stuck on the back of the belt enables tensioning or idler pulleys to be used and thus, together with the aramid tensile cords and the chloroprene rubber mix, an incredibly efficient power transmission is achieved, even if severe stress caused by heat, humidity, oil and acids has to be factored into the equation.

Properties

- Suitable for demanding applications where easily strained FHP belts can stretch or tear

- Particularly impact-resistant

- Tensile cord made out of aramid fibres to guarantee outstanding length stability

- Delivers fantastic performance power as opposed to quickly strained FHP belts

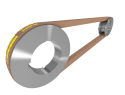

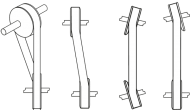

- Treated with a special coating on the outer edge to enable the use of applications with idler pulleys on the back of the belt

- Extremely heat, oil and damp-proof

- Extremely tear-resistant

Application:

- The agricultural sector

- Care of lawns, landscape conservation and garden maintenance

- HVAC (Heating, ventilation and air-conditioning systems)

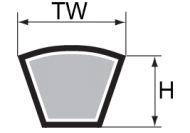

| Typ | TW | H | ||

| Inch | mm | Inch | mm | |

| 3L | 3/8 | 9,5 | 7/32 | 5,5 |

| 4L | 1/2 | 12,7 | 5/16 | 7,9 |

| 5L | 21/32 | 16,5 | 3/8 | 9,5 |

| Available belt pitches | 3LK | 4LK | 5LK | |||

| Belt type | mantled | |||||

| Doouble V-Belt available? | no | no | no | |||

| Tolerance according to: | MBL | |||||

| Belt material | Rubber | Chloroprene | ||||

| Tensile member | Aramid | |||||

| fabric | Cotton | |||||

| electrical conductivity | yes | |||||

| Temperature-range | -30 ~ +90 | |||||

| Wear resistance | good | |||||

| Heat resistance | good | |||||

| max. belt speed | (m/s) | 25 | ||||

| Weight | (kg/m) | 0.12 | 0.20 | 0.35 | ||

| available lengths | (inch) | 20-76 | 20-99 | 20-99 | ||

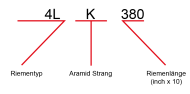

Super KB Order Reference

| Standard belt size (inch) |

||

| Belt type | Size range | |

| 3LK | 20-76 | |

| 4LK | 20-99 | |

| 5LK | 20-99 | |

| Minimum pulley size FHP belt (mm) | |||||

| Belt type | Recommended minimum dimension of pulley size | Permitted minimum dimension of pulley size | |||

| Outer diameter |

Pitch diameter |

Outer diameter |

Pitch diameter |

||

| 3LK | 79 | 70 | 59 | 50 | |

| 4LK | 101 | 90 | 109 | 95 | |

| 5LK | 129 | 115 | 109 | 95 | |

Alongside our wide standard range of this product, we also craft in our ateliers high-precision drawing parts and customised special pulley washers. With all our products we offer a comprehensive service ranging from the manufacturing of mechanical processing parts and gearing components right up to the mounting of finished systems and assembly units.

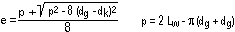

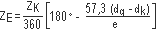

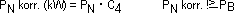

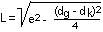

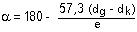

Pre-Tensioning The Belt Correctly

Firstly the belt always has to be tightened in line with the calculated pre-tensioning force and checked after a running-in period of about 5 minutes. The belt is then to be retightened according to the relevant value, should it have shifted or altered its position in any way. Finally after a further 8 hours of operating, the belt is to be once again inspected and, if necessary, tightened to comply with the required value that has already been calculated.

Causes of failure and corrective measures can be found in the following document:

Troubleshooting for power transmission products