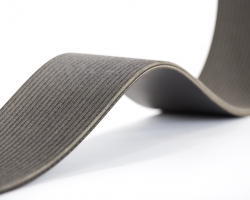

Poly V-Belts / Ribstar G / Ribbed V-Belts

In the world of mechanical engineering, demands for higher levels of efficiency, for more features and functions and for longer-lasting products have all risen as a result of a sea change in materials. The MITSUBOSHI "Ribstar", a ribbed V-belt for industrial applications, was developed and created in order to meet such requirements. Only after production is the profile cut into the belt so as to guarantee a product steeped in unchanging top-class quality.

Special Designs

Special rubber compounds such as EPDM and tensile cords made of aramid are available on request.

The characteristics of V-belts that are conducive to high power transmission and the flexibility of flat belts join forces in these special belts and excel even more thanks to the following properties:

- Efficient running at high speeds

- Operation possible on small diameter pulley wheels

- Excellent heat resistance and friction resistance

- Suitable for compactly-designed applications

- Only slight belt vibration

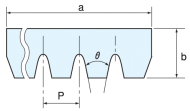

| J | PK | L | |

| a | 2,34 x N | 3,56 x N | 4,70 x N |

| b | 3,80 | 5,00 | 7,50 |

| P | 2,34 | 3,56 | 4,70 |

| θ(°) | 40 | 40 | 40 |

| N = Number of ribs All specifications in mm |

|||

| Belt material | Chloroprene | |

| Belt type | Polished profile | |

| Length tolerance | ISO 9982 | |

| Tensile member | Polyester | |

| electrical conductivity | yes | |

| Temperature range | -30°C bis + 80°C | |

| Wear resistance | normal | |

| reenforced | on request | |

| max. speed | 45 m/s | |

| Multi V-Belt available? | ja | |

| Weight | J: 0,01 kg / Rib-Meter | |

| K: 0,02 kg / Rib-Meter | ||

| L: 0,04 kg / Rib-Meter |

| Size code | Effective Diameter (mm) |

Size code | Effective Diameter (mm) |

|

| 180J | 457 | 360J | 914 | |

| 190J | 483 | 370J | 940 | |

| 200J | 508 | 375J | 953 | |

| 210J | 533 | 380J | 965 | |

| 220J | 559 | 390J | 991 | |

| 235J | 597 | 400J | 1.016 | |

| 240J | 610 | 410J | 1.041 | |

| 245J | 622 | 420J | 1.067 | |

| 250J | 635 | 430J | 1.092 | |

| 260J | 660 | 440J | 1.118 | |

| 270J | 686 | 450J | 1.143 | |

| 280J | 711 | 460J | 1.168 | |

| 290J | 737 | 480J | 1.219 | |

| 300J | 762 | 490J | 1.245 | |

| 310J | 787 | 510J | 1.295 | |

| 315J | 800 | 530J | 1.346 | |

| 320J | 813 | 550J | 1.397 | |

| 330J | 838 | 580J | 1.473 | |

| 340J | 864 | 610J | 1.549 | |

| 345J | 876 | 650J | 1.651 | |

| 350J | 889 | 730J | 1.854 |

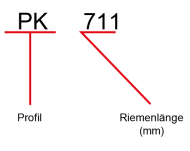

| Size code | Effective Diameter (mm) |

Size code | Effective Diameter (mm) |

|||

| PK | 600 | 600 | PK | 1250 | 1250 | |

| PK | 615 | 615 | PK | 1280 | 1280 | |

| PK | 630 | 630 | PK | 1320 | 1320 | |

| PK | 650 | 650 | PK | 1360 | 1360 | |

| PK | 690 | 690 | PK | 1400 | 1400 | |

| PK | 710 | 710 | PK | 1450 | 1450 | |

| PK | 730 | 730 | PK | 1500 | 1500 | |

| PK | 750 | 750 | PK | 1550 | 1550 | |

| PK | 775 | 775 | PK | 1600 | 1600 | |

| PK | 800 | 800 | PK | 1650 | 1650 | |

| PK | 825 | 825 | PK | 1700 | 1700 | |

| PK | 850 | 850 | PK | 1750 | 1750 | |

| PK | 875 | 875 | PK | 1800 | 1800 | |

| PK | 900 | 900 | PK | 1850 | 1850 | |

| PK | 925 | 925 | PK | 1900 | 1900 | |

| PK | 950 | 950 | PK | 1950 | 1950 | |

| PK | 975 | 975 | PK | 2000 | 2000 | |

| PK | 1000 | 1000 | PK | 2120 | 2120 | |

| PK | 1030 | 1030 | PK | 2240 | 2240 | |

| PK | 1060 | 1060 | PK | 2360 | 2360 | |

| PK | 1090 | 1090 | PK | 2500 | 2500 | |

| PK | 1120 | 1120 | PK | 2650 | 2650 | |

| PK | 1150 | 1150 | PK | 2800 | 2800 | |

| PK | 1180 | 1180 | PK | 3000 | 3000 | |

| PK | 1220 | 1220 | ||||

| Size code | Effective Diameter (mm) |

Size code | Effective Diameter (mm) |

|

| 345L | 876 | 600L | 1.524 | |

| 350L | 889 | 615L | 1.562 | |

| 355L | 902 | 635L | 1.613 | |

| 360L | 914 | 650L | 1.651 | |

| 370L | 940 | 655L | 1.664 | |

| 375L | 953 | 675L | 1.715 | |

| 380L | 965 | 680L | 1.727 | |

| 385L | 978 | 690L | 1.753 | |

| 390L | 991 | 725L | 1.842 | |

| 395L | 1.003 | 750L | 1.905 | |

| 400L | 1.016 | 765L | 1.943 | |

| 405L | 1.029 | 780L | 1.981 | |

| 410L | 1.041 | 815L | 2.070 | |

| 415L | 1.054 | 835L | 2.121 | |

| 420L | 1.067 | 845L | 2.146 | |

| 425L | 1.080 | 865L | 2.197 | |

| 430L | 1.092 | 880L | 2.235 | |

| 450L | 1.143 | 915L | 2.324 | |

| 460L | 1.168 | 930L | 2.362 | |

| 480L | 1.219 | 975L | 2.477 | |

| 500L | 1.270 | 990L | 2.515 | |

| 540L | 1.372 | 1065L | 2.705 | |

| 560L | 1.422 | 1120L | 2.845 | |

| 565L | 1.435 | 1150L | 2.921 | |

| 570L | 1.448 | |||

| Only available on order | ||||

Alongside our wide standard range of this product, we also craft in our ateliers high-precision drawing parts and customised special pulley washers. With all our products we offer a comprehensive service ranging from the manufacturing of mechanical processing parts and gearing components right up to the mounting of finished systems and assembly units.

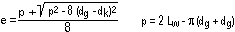

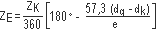

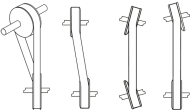

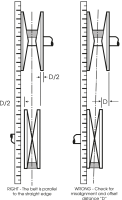

Pre-Tensioning The Belt Correctly

Firstly the belt always has to be tightened in line with the calculated pre-tensioning force and checked after a running-in period of about 5 minutes. The belt is then to be retightened according to the relevant value, should it have shifted or altered its position in any way. Finally after a further 8 hours of operating, the belt is to be once again inspected and, if necessary, tightened to comply with the required value that has already been calculated.

Causes of failure and corrective measures can be found in the following document:

Troubleshooting for power transmission products

| Belt length mm |

minimal adjustment for installation (mm) |

Required adjustemnt range for tightening |

||

| J | L | |||

| up to 508 | 10,16 | 7,62 | ||

| up to 508 - 1016 | 12,70 | 12,70 | ||

| up to 1016 - 1524 | 15,24 | 22,86 | 17,78 | |

| up to 1524 - 2032 | 15,24 | 22,86 | 22,86 | |

| up to 2032 - 2540 | 17,78 | 25,40 | 27,94 | |

| up to 2540 - 3048 | 20,32 | 27,94 | 33,02 | |

| up to 3048 - 4064 | 30,48 | 43,18 | ||

| up to 4064 - 5080 | 33,02 | 55,88 | ||

| up to 5080 - 6096 | 35,56 | 66,04 | ||

| up to 6096 - 7620 | 83,82 | |||

| up to 7620 - 9144 | 99,06 | |||

| up to 9144 - 10668 | 116,84 | |||

| up to 10668 - 12192 | 132,08 | |||

| up to 12192 - 13716 | 147,32 | |||

| up to 13716 - 15240 | 165,10 | |||