Megatorque

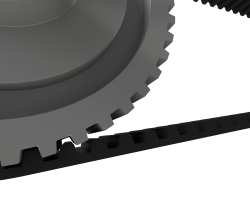

1. Tooth reinforcement made of nylon, 2. Strengthened glass fibre tensile cord, 3. Belt teeth made of hydrogenated nitrile butadiene rubber (HNBR), 4. Belt backing made of HNBR

Even with the SuperTorque high-powered timing belt, Mitsuboshi succeeded in breaking new ground and introducing new standards in drive technology. These heights have now been taken to an even higher level: with the new MegaTorque - distributed by Krebs & Kessel! Doubled performance, an even bigger helping of reliability, longer service lifespan and a marked increase in efficiency are the superlative hallmarks of this innovational generation of timing belts. They herald in even more efficiency in countless fields of application - they guarantee optimal results under all kinds of conditions.

- Technical Details

- Belt Sizes

- Standard Tooth Lock Washers

- Special Tooth Lock Washers

- Installation and Mounting

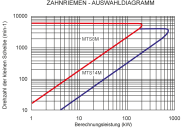

- Selection Diagram

- Performance Tables

- Calculation Factors

Advantages gained by the tooth geometry of the new MEGATORQUE

Harmonious tooth geometry is by its very nature the overriding recipe for success in a top-flight belt. And in this respect the new MegaTorque stands out in the crowd with some very lucid facts in its favour:

-

Round edges allow smooth meshing of the teeth

Large tooth volume and 50% more teeth in the mesh than is found with comparable standard timing belts - Reduced shear force as a result of more even stress distribution on teeth

- High jumping torque and superior smoothness

- Power transmission showing almost no play and with SE toothed lock washers

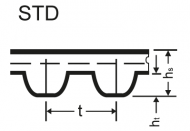

| Code | mm | hs | hd | ht | t | s | ra | rr | r | Effective pitch distance mm |

| MTS8M | 8,00 | 5,30 | 7,47 | 3,05 | 2,25 | 5,20 | 0,80 | 0,80 | 5,20 | 0,686 |

| MTS14M | 14,00 | 10,20 | 13,39 | 5,30 | 4,90 | 9,10 | 1,40 | 1,40 | 9,10 | 1,397 |

| Effective belt length mm |

length tolerance mm |

Centre distance mm |

Measurement y* |

| > 254 up to 381 | ± 0,46 | ± 0,23 | 15 |

| > 381 up to 508 | ± 0,50 | ± 0,25 | 15 |

| > 508 up to 762 | ± 0,60 | ± 0,30 | 15 |

| > 762 up to 1016 | ± 0,66 | ± 0,33 | 15 |

| > 1016 up to 1270 | ± 0,76 | ± 0,38 | 15 |

| > 1270 up to 1514 | ± 0,81 | ± 0,405 | 15 |

| > 1524 up to 1778 | ± 0,86 | ± 0,43 | 15 |

| > 1778 up to 2032 | ± 0,92 | ± 0,46 | 15 |

| > 2032 up to 2286 | ± 0,96 | ± 0,48 | 15 |

| > 2286 up to 2540 | ± 1,02 | ± 0,51 | 15 |

| > 2540 up to 2794 | ± 1,06 | ± 0,53 | 15 |

| > 2794 up to 3048 | ± 1,12 | ± 0,56 | 15 |

| > 3048 up to 3302 | ± 1,17 | ± 0,585 | 15 |

| > 3302 up to 3556 | ± 1,22 | ± 0,61 | 15 |

| > 3556 up to 3810 | ± 1,27 | ± 0,635 | 15 |

| > 3810 up to 4064 | ± 1,37 | ± 0,81 | 15 |

| > 4064 up to 4318 | ± 1,42 | ± 0,685 | 15 |

| > 4318 up to 4572 | ± 1,52 | ± 0,71 | 15 |

| > 4572 up to 5012 | ± 1,62 | ± 0,76 | 15 |

| *If mounting conditions are difficult, the centre distance should be able to be reduced by the amount of "y" so that the timing belt can be fitted easefully. And balancing of the centre distance tolerance given ought to be possible in every situation. | |||

| Timing belt width mm |

Width tolerance for belt length mm | |||

| < 351 | > 351 - 840 | > 840 - 1680 | > 1680 | |

| < 10 | + 0,3 | + 0,3 | + 0,6 | |

| - 0,6 | - 0,6 | - 0,6 | ||

| > 10 - 40 | + 0,8 | + 0,8 | + 0,8 | + 0,8 |

| - 0,8 | - 0,8 | - 1,2 | - 1,2 | |

| > 40 - 50 | + 0,8 | + 1,2 | + 1,2 | |

| - 0,8 | - 1,6 | - 1,6 | ||

| > 50 - 75 | + 1,6 | + 1,6 | ||

| - 2,0 | - 2,0 | |||

| > 75 - 100 | + 2,0 | + 2,0 | ||

| - 2,0 | - 2,0 | |||

| > 100 | + 2,4 | + 2,4 | ||

| - 3,2 | - 3,2 | |||

| Profile code | Belt thickness/Tolerance mm | ||

| S1 | S2 | ||

| MTS8M | 5,3 ± 0,20 | 2,25 ± 0,20 | |

| MTS14M | 10,20 ± 1,00 | 4,90 + 1,00 | |

| -0.8 | |||

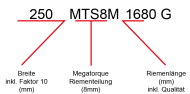

MegaTorque Order Reference

| Belt no. | Teeth no. | Effective belt length mm |

| MTS8M 560 G | 70 | 560 |

| MTS8M 854 G | 73 | 584 |

| MTS8M 600 G | 75 | 600 |

| MTS8M 632 G | 79 | 632 |

| MTS8M 640 G | 80 | 640 |

| MTS8M 656 G | 82 | 656 |

| MTS8M 680 G | 85 | 680 |

| MTS8M 712 G | 89 | 712 |

| MTS8M 720 G | 90 | 720 |

| MTS8M 760 G | 95 | 760 |

| MTS8M 800 G | 100 | 800 |

| MTS8M 824 G | 103 | 824 |

| MTS8M 848 G | 106 | 848 |

| MTS8M 880 G | 110 | 880 |

| MTS8M 896 G | 112 | 896 |

| MTS8M 976 G | 122 | 976 |

| MTS8M 984 G | 123 | 984 |

| MTS8M 1000 G | 125 | 1000 |

| MTS8M 1024 G | 128 | 1024 |

| MTS8M 1040 G | 130 | 1040 |

| MTS8M 1056 G | 132 | 1056 |

| MTS8M 1080 G | 135 | 1080 |

| MTS8M 11220 G | 140 | 1120 |

| MTS8M 1128 G | 141 | 1128 |

| MTS8M 1136 G | 142 | 1136 |

| MTS8M 1160 G | 145 | 1160 |

| MTS8M 1200 G | 150 | 1200 |

| MTS8M 1248 G | 156 | 1248 |

| MTS8M 1256 G | 157 | 1256 |

| MTS8M 1280 G | 160 | 1280 |

| MTS8M 1304 G | 163 | 1304 |

| MTS8M 1320 G | 165 | 1320 |

| MTS8M 1352 G | 169 | 1352 |

| MTS8M 1360 G | 170 | 1360 |

| MTS8M 1400 G | 175 | 1400 |

| MTS8M 1424 G | 178 | 1424 |

| MTS8M 1440 G | 180 | 1440 |

| MTS8M 1448 G | 181 | 1448 |

| MTS8M 1480 G | 185 | 1480 |

| MTS8M 1520 G | 190 | 1520 |

| MTS8M 1600 G | 200 | 1600 |

| MTS8M 1640 G | 205 | 1640 |

| MTS8M 1648 G | 206 | 1648 |

| MTS8M 1680 G | 210 | 1680 |

| MTS8M 1696 G | 212 | 1696 |

| MTS8M 1728 G | 216 | 1728 |

| MTS8M 1760 G | 220 | 1760 |

| MTS8M 1776 G | 222 | 1776 |

| MTS8M 1800 G | 225 | 1800 |

| MTS8M 1816 G | 227 | 1816 |

| MTS8M 1832 G | 229 | 1832 |

| MTS8M 1880G | 235 | 1880 |

| MTS8M 1912 G | 239 | 1912 |

| MTS8M 2000 G | 250 | 2000 |

| MTS8M 2040 G | 255 | 2040 |

| MTS8M 2048 G | 256 | 2048 |

| MTS8M 2160 G | 270 | 2160 |

| MTS8M 2240 G | 280 | 2240 |

| MTS8M 2272 G | 284 | 2272 |

| MTS8M 2304 G | 288 | 2304 |

| MTS8M 2376 G | 297 | 2376 |

| MTS8M 2400 G | 300 | 2400 |

| MTS8M 2496 G | 312 | 2496 |

| MTS8M 2600 G | 325 | 2600 |

| MTS8M 2800 G | 350 | 2800 |

| MTS8M 2920 G | 365 | 2920 |

| MTS8M 3048 G | 381 | 3048 |

| MTS8M 3200 G | 400 | 3200 |

| MTS8M 3272 G | 409 | 3272 |

| MTS8M 3680 G | 460 | 3680 |

| MTS8M 4400 G | 550 | 4400 |

| Belt no. | Teeth no. | Effective belt length mm |

| MTS14M 1008 G | 72 | 1008 |

| MTS14M 1120 G | 80 | 1120 |

| MTS14M 1190 G | 85 | 1190 |

| MTS14M 1246 G | 89 | 1246 |

| MTS14M 1400 G | 100 | 1400 |

| MTS14M 1540 G | 110 | 1540 |

| MTS14M 1610 G | 115 | 1610 |

| MTS14M 1750 G | 125 | 1750 |

| MTS14M 1778 G | 127 | 1778 |

| MTS14M 1806 G | 129 | 1806 |

| MTS14M 1890 G | 135 | 1890 |

| MTS14M 1932 G | 138 | 1932 |

| MTS14M 2002 G | 143 | 2002 |

| MTS14M 2100 G | 150 | 2100 |

| MTS14M 2198 G | 157 | 2198 |

| MTS14M 2240 G | 160 | 2240 |

| MTS14M 2310 G | 165 | 2310 |

| MTS14M 2380 G | 170 | 2380 |

| MTS14M 2450 G | 175 | 2450 |

| MTS14M 2506 G | 179 | 2506 |

| MTS14M 2590 G | 185 | 2590 |

| MTS14M 2660 G | 190 | 2660 |

| MTS14M 2800 G | 200 | 2800 |

| MTS14M 3150 G | 225 | 3150 |

| MTS14M 3500 G | 250 | 3500 |

| MTS14M 3556 G | 254 | 3556 |

| MTS14M 3850 G | 275 | 3850 |

| MTS14M 4004 G | 286 | 4004 |

| MTS14M 4508 G | 322 | 4508 |

| MTS14M 5012 G | 358 | 5012 |

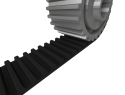

When it comes to synchronised belts, the toothed profile of the MegaTorque top-performance timing belt is a patented innovation. The gaps between the teeth on the pulley washers of the MegaTorque, high-powered belt differ from those on previously designed profiles.

Because of its special shape, the profile formed by the spaces between the teeth guarantees optimal meshing of the timing belt teeth. The depth of the space between each tooth is less than the height of the teeth making up the MegaTorque high-powered belt. And this, together with the arched curvature of the gap between each pulley washer, means that tension is spread more evenly over the entire stretch of belt teeth.

Tooth Lock Washers with SE Tooth System

For all those timing belt drives which demand the highest level of synchronicity, such as

- Robots

- Handling devices

- Machine tool feeds

- Printing machines

- Writing computers

- Optical readers

and the like, we recommend washers with an SE tooth design. The gaps between the teeth, which are meticulously formed by means of special milling machines, enable the MegaTorque timing belt drive to be virtually free of any kind of play. This SE tooth system is available for the standard profiles of S2M, S3M, S4.5M, S5M, S8M and S14M.

When it comes to synchronised belts, the toothed profile of the MegaTorque top-performance timing belt is a patented innovation. The gaps between the teeth on the pulley washers of the MegaTorque, high-powered belt differ from those on previously designed profiles.

Because of its special shape, the profile formed by the spaces between the teeth guarantees optimal meshing of the timing belt teeth. The depth of the space between each tooth is less than the height of the teeth making up the MegaTorque high-powered belt. And this, together with the arched curvature of the gap between each pulley washer, means that tension is spread more evenly over the entire stretch of belt teeth.

Exceptionally High Manufacturing Precision

MegaTorque top-performance timing belts are produced with the highest degree of precision. Manufacturing tolerances as regards length, width and thickness are minimal and are determined in line with commercially profitable manufacturing processes. Should, however, narrower tolerances be absolutely essential, we recommend a technical consultation with us on this issue.

Gap Profile of Tooth Lock Washers

It is imperative that the gaps between the teeth of the washers making up the SuperTorque timing belt correspond exactly to the pitch and that they are manufactured according to the recommended range of tolerance. Only by adhering to the specified dimensions can utmost strength and smooth running with virtually no signs of play be guaranteed for the SuperTorque timing belt.

Tooth Lock Washers - The Materials

The most diverse types of materials, such as sintered metal, plastics, aluminium, steel, grey cast iron and cast steel, can be used to make tooth lock washers. But the material is primarily chosen so as to best suit the intended use and the demands in question, whereby particular attention should be paid to ensuring that adequate resistance to wear is present. In the case of substantial series production requirements, manufacturing tooth lock washers using the full mould process (injection moulding or pressure die-casting) is the most appropriate method.

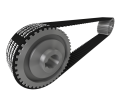

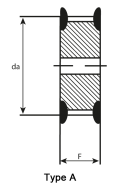

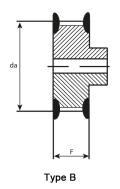

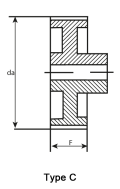

Flanged Wheels

Flanged wheels or pulleys prevent the wearing down of timing belts. It is necessary that at least one of the tooth lock washers - for cost reasons usually the smaller one - is fitted with 2 flanged wheels. The mounting of 1 flanged wheel on both sides of each tooth lock washer is also possible. With drives having a centre distance greater than 8 times dw, it is recommendable to attach 2 flanged wheels per tooth lock washer.

Parallelism

The teeth should run parallel to the axis of the borehole with a maximum deviation of 0.001 mm per millimetre of the width.

Conicity

The conicity can only amount to a maximum of 0.001 mm per millimetre in the head width and, at the same time, is not to exceed the permissible diameter tolerance.

Surface Quality in accordance with ISO R 468

The surface quality is not to exceed the value of Ra=3,2 µm for tooth flanks and tooth crest.

Balancing

With tooth lock washers that are processed on both sides, balancing is usually not necessary up to a peripheral velocity of 30 m/s. But cast discs are even to be balanced at v < 30 m/s.

The following is a general rule of thumb:

- Balancing in one plane, quality level Q 16 in accordance with VDI 2060 at v = 30 m/s for dw>400 mm or at n = 1500 min-1 for dw 400 mm.

- Balancing on two planes with the recommendation Q 6.3 at v > 30 m/s or at v> 20 m/s at a ratio of effective diameter to tooth lock washer width < 4.

Balancing is carried out on ungrooved tooth lock washers by means of a smooth balancing mandrel.

Further details can be found in ISO 254 and in the VDI Guideline 2060.

| Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) |

| 18 | 45,84 | 44,46 | 61 | 155,34 | 153,96 | 104 | 264,83 | 263,46 |

| 19 | 48,38 | 47,01 | 62 | 157,88 | 156,51 | 105 | 267,38 | 266,01 |

| 20 | 50,39 | 49,56 | 63 | 160,43 | 159,06 | 106 | 269,93 | 268,55 |

| 21 | 53,48 | 52,10 | 64 | 162,97 | 161,60 | 107 | 272,47 | 271,10 |

| 22 | 56,02 | 54,65 | 65 | 165,52 | 164,15 | 108 | 275,02 | 273,65 |

| 23 | 58,57 | 57,20 | 66 | 168,07 | 166,70 | 109 | 277,57 | 276,19 |

| 24 | 61,12 | 59,74 | 67 | 170,61 | 169,24 | 110 | 280,11 | 278,74 |

| 25 | 63,66 | 62,29 | 68 | 173,16 | 171,79 | 11 | 282,66 | 281,29 |

| 26 | 66,21 | 64,84 | 69 | 175,71 | 174,34 | 112 | 285,21 | 283,83 |

| 27 | 68,75 | 67,38 | 70 | 178,25 | 176,88 | 113 | 287,75 | 286,38 |

| 28 | 71,30 | 69,93 | 71 | 180,80 | 179,43 | 114 | 290,30 | 288,93 |

| 29 | 73,85 | 72,48 | 72 | 183,35 | 181,97 | 115 | 292,85 | 291,47 |

| 30 | 76,39 | 75,02 | 73 | 185,89 | 184,52 | 116 | 295,39 | 294,02 |

| 31 | 78,94 | 77,57 | 74 | 188,44 | 187,07 | 117 | 297,94 | 296,57 |

| 32 | 81,49 | 80,12 | 75 | 190,99 | 189,61 | 118 | 300,48 | 299,11 |

| 33 | 84,03 | 82,66 | 76 | 193,53 | 192,16 | 119 | 303,03 | 301,66 |

| 34 | 86,58 | 85,21 | 77 | 196,08 | 194,71 | 120 | 305,58 | 304,21 |

| 35 | 89,13 | 87,75 | 78 | 198,63 | 197,25 | 121 | 308,12 | 306,75 |

| 36 | 91,67 | 90,30 | 79 | 201,17 | 199,80 | 122 | 310,67 | 309,30 |

| 37 | 94,22 | 92,85 | 80 | 203,72 | 202,35 | 123 | 313,22 | 311,84 |

| 38 | 96,77 | 95,39 | 81 | 206,26 | 204,89 | 124 | 315,76 | 314,39 |

| 39 | 99,31 | 97,94 | 82 | 208,81 | 207,44 | 125 | 318,31 | 316,94 |

| 40 | 101,86 | 100,49 | 83 | 211,36 | 209,99 | 126 | 320,86 | 319,48 |

| 41 | 104,41 | 103,03 | 84 | 213,90 | 212,53 | 127 | 323,40 | 322,03 |

| 42 | 106,95 | 105,58 | 85 | 216,45 | 215,08 | 128 | 325,95 | 324,58 |

| 43 | 109,50 | 108,13 | 86 | 219,00 | 217,63 | 129 | 328,50 | 327,12 |

| 44 | 112,05 | 110,67 | 87 | 221,54 | 220,17 | 130 | 331,04 | 329,67 |

| 45 | 114,59 | 113,22 | 88 | 224,09 | 222,72 | 131 | 333,59 | 332,22 |

| 46 | 117,14 | 115,77 | 89 | 226,64 | 225,26 | 132 | 336,14 | 334,76 |

| 47 | 119,68 | 118,31 | 90 | 229,18 | 227,81 | 133 | 338,68 | 337,31 |

| 48 | 122,23 | 120,86 | 91 | 231,73 | 230,36 | 134 | 341,23 | 339,86 |

| 49 | 124,78 | 123,41 | 92 | 234,28 | 232,90 | 135 | 343,77 | 342,40 |

| 50 | 127,32 | 125,95 | 93 | 236,82 | 235,45 | 136 | 346,32 | 344,95 |

| 51 | 129,87 | 128,50 | 94 | 239,37 | 238,00 | 137 | 348,87 | 347,50 |

| 52 | 132,42 | 131,04 | 95 | 241,92 | 240,54 | 138 | 351,41 | 350,04 |

| 53 | 134,96 | 133,59 | 86 | 244,46 | 243,09 | 139 | 353,96 | 352,59 |

| 54 | 137,51 | 136,14 | 67 | 247,01 | 245,64 | 140 | 356,51 | 355,14 |

| 55 | 140,06 | 138,68 | 98 | 249,56 | 248,18 | 141 | 359,05 | 357,68 |

| 56 | 142,60 | 141,23 | 99 | 252,10 | 250,73 | 142 | 361,60 | 360,23 |

| 57 | 145,15 | 143,78 | 100 | 254,65 | 253,28 | 143 | 364,15 | 362,77 |

| 58 | 147,70 | 146,32 | 101 | 257,19 | 255,82 | 144 | 366,69 | 365,32 |

| 59 | 150,24 | 148,87 | 102 | 259,74 | 258,37 | |||

| 60 | 152,79 | 151,42 | 103 | 262,29 | 260,92 |

| Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) |

| 28 | 124,78 | 121,98 | 70 | 311,94 | 309,15 | 112 | 499,11 | 496,32 |

| 29 | 129,23 | 126,44 | 71 | 316,40 | 313,61 | 113 | 503,57 | 500,77 |

| 30 | 133,69 | 130,90 | 72 | 320,86 | 318,06 | 114 | 508,02 | 505,23 |

| 31 | 138,15 | 135,35 | 73 | 325,31 | 322,52 | 115 | 512,48 | 509,68 |

| 32 | 142,60 | 139,81 | 74 | 329,77 | 326,98 | 116 | 516,94 | 514,14 |

| 33 | 147,06 | 144,27 | 75 | 334,23 | 331,43 | 117 | 521,39 | 518,60 |

| 34 | 151,52 | 148,72 | 76 | 338,68 | 335,89 | 118 | 525,85 | 523,05 |

| 35 | 155,97 | 153,18 | 77 | 343,14 | 340,34 | 119 | 530,30 | 527,51 |

| 36 | 160,43 | 157,63 | 78 | 347,59 | 344,80 | 120 | 534,76 | 531,97 |

| 37 | 164,88 | 162,09 | 79 | 352,05 | 349,26 | 121 | 539,22 | 536,42 |

| 38 | 169,34 | 166,55 | 80 | 356,51 | 353,71 | 122 | 543,67 | 540,88 |

| 39 | 173,80 | 171,00 | 81 | 360,96 | 358,17 | 123 | 548,13 | 545,34 |

| 40 | 178,25 | 175,46 | 82 | 365,42 | 362,63 | 124 | 552,59 | 549,79 |

| 41 | 182,71 | 179,92 | 83 | 369,88 | 367,08 | 125 | 557,04 | 554,25 |

| 42 | 197,17 | 184,37 | 84 | 374,33 | 371,54 | 126 | 561,50 | 558,70 |

| 43 | 191,62 | 188,83 | 85 | 378,79 | 375,99 | 127 | 565,96 | 563,16 |

| 44 | 196,08 | 193,28 | 86 | 383,25 | 380,45 | 128 | 570,41 | 567,62 |

| 45 | 200,54 | 197,74 | 87 | 387,70 | 384,91 | 129 | 574,87 | 572,07 |

| 46 | 204,99 | 202,20 | 88 | 392,16 | 389,36 | 130 | 579,32 | 576,53 |

| 47 | 209,45 | 206,65 | 89 | 396,61 | 393,82 | 131 | 583,78 | 580,99 |

| 48 | 213,90 | 211,11 | 90 | 401,07 | 398,28 | 132 | 588,24 | 585,44 |

| 49 | 218,36 | 215,57 | 91 | 405,53 | 402,73 | 133 | 592,69 | 589,90 |

| 50 | 222,82 | 220,02 | 92 | 409,98 | 407,19 | 134 | 597,15 | 594,36 |

| 51 | 227,27 | 224,48 | 93 | 414,44 | 411,65 | 135 | 601,61 | 598,81 |

| 52 | 231,73 | 228,94 | 94 | 418,90 | 416,10 | 136 | 606,06 | 603,27 |

| 53 | 236,19 | 233,39 | 95 | 423,35 | 420,56 | 137 | 610,52 | 607,72 |

| 54 | 240,64 | 237,85 | 96 | 427,81 | 425,01 | 138 | 614,97 | 612,18 |

| 55 | 245,10 | 242,30 | 97 | 432,26 | 429,47 | 139 | 619,43 | 616,64 |

| 56 | 249,56 | 246,76 | 98 | 436,72 | 433,93 | 140 | 623,89 | 621,09 |

| 57 | 254,01 | 251,22 | 99 | 441,18 | 438,38 | 141 | 628,34 | 625,55 |

| 58 | 258,47 | 255,67 | 100 | 445,63 | 442,84 | 142 | 632,80 | 630,01 |

| 59 | 262,92 | 260,13 | 101 | 450,09 | 447,30 | 143 | 637,26 | 634,46 |

| 60 | 267,38 | 264,59 | 102 | 454,55 | 451,75 | 144 | 641,71 | 638,92 |

| 61 | 271,84 | 269,04 | 103 | 459,00 | 456,21 | 145 | 646,17 | 643,38 |

| 62 | 276,29 | 273,50 | 104 | 463,46 | 460,67 | 146 | 650,63 | 647,83 |

| 63 | 280,75 | 277,96 | 105 | 467,92 | 465,12 | 147 | 655,08 | 652,29 |

| 64 | 285,21 | 282,41 | 106 | 472,37 | 469,58 | 148 | 659,54 | 656,74 |

| 65 | 289,66 | 286,87 | 107 | 476,83 | 474,03 | 149 | 663,99 | 661,20 |

| 66 | 294,12 | 291,32 | 108 | 481,28 | 478,49 | 150 | 668,45 | 665,66 |

| 67 | 298,57 | 295,78 | 109 | 485,74 | 482,95 | |||

| 68 | 303,03 | 300,24 | 110 | 490,20 | 487,40 | |||

| 69 | 307,49 | 304,69 | 111 | 494,65 | 491,86 |

| Tolerances of outer diameter | ||||

| Outer diameter | Permitted tolerance |

Permitted rotational deviation |

Rough turning Oversize (da) + |

|

| mm from | mm to | mm | mm | mm |

| 0 | 50 | +0,05 | 0,04 | 1 |

| 51 | 100 | +0,08 | 0,05 | |

| 101 | 150 | +0,10 | 0,07 | |

| 151 | 200 | +0,12 | 0,10 | |

| 201 | 300 | +0,15 | 0,12 | |

| 301 | 500 | +0,18 | +0,03 pro 100mm Outer diameter |

|

| 501 | ... | +0,20 | ||

| Axial run-out tolerance | |

| Outer diameter | Permitted rotational deviation |

| mm | mm |

| bis 101,60 | 0.1 |

| über 101,60 bis 250,00 |

0,1 +0,1mm pro 100mm Outer diameter |

| über 251,00 | 0,25 +0,05mm pro 100mm Outer diameter |

| Surface Rz | |

| Pitch | permitted peak-to-valley roughness Rz |

| 8 mm | Rz < 16 |

| 14 mm | Rz < 25 |

In order to achieve optimal performance and as long a service life as possible, timing belts have to be correctly installed, correctly tightened and correctly aligned. Prior to installation, it is always recommendable to inspect the belts for any possible damage resulting from transport or storage.

The Correct Mounting

Pulleys and, of course, belts themselves always have to be mounted with the correct alignment. This means that belts cannot be bent or buckled in any way, which could lead to a drop below the minimum permissible pulley diameter. That corresponds to approximately 50 mm for belts with a pitch of 8 mm and about 125 mm for those belts with a 14 mm pitch. Imbalanced drives cause a variety of belt tension problems and edge stresses and are also responsible for extreme lateral movement, the undesired wobble. All this leads to increased operating noise and more wear and tear on the belt. Therefore the parallelism error of the pulleys should only amount to a maximum of 0.5% of the centre distance. Angle accuracy is to be maintained by keeping misalignment down to 0.25° at the very most.

Pre-Tensioning The Belt Correctly

Firstly the belt always has to be tightened in line with the calculated pre-tensioning force and checked after a running-in period of about 5 minutes. The belt is then to be retightened according to the relevant value, should it have shifted or altered its position in any way. Finally after a further 8 hours of operating, the belt is to be once again inspected and, if necessary, tightened to comply with the required value that has already been calculated.

Causes of failure and corrective measures can be found in the following document:

Troubleshooting for power transmission products

| Belt length mm |

Minimal adjustment for installation |

Required adjustment range for tightening |

|

| 8M | 14M | 8M, 14M | |

| smaller than 1525 | 34,5 mm | 59,5 mm | 2,5 mm |

| 1525 - 3050 | 37,0 mm | 62,0 mm | 5,0 mm |

| greater than 3050 | 39,5 mm | 64,5 mm | 7,5 mm |

Always ready for action: The MEGATORQUE from Mitsuboshi

Fu permissible for belt width ⋛ 60mm

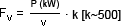

Specific basic performance in [kW] = Pn x width factor

| Belt width b (mm) | 15 | 20 | 25 | 30 | 40 | 50 | 60 |

| Fupermissable (N) | 1155 | 1603 | 2068 | 2545 | 3533 | 4556 | 5609 |

| Width Factor BF | 0.21 | 0.29 | 0.37 | 0.45 | 0.63 | 0.81 | 1.00 |

| Teeth no. | 24 | 26 | 28 | 30 | 32 | 34 | 36 | 38 | 40 | 42 | 44 | 46 | 48 | 50 | 60 | 72 | 84 |

| dw | 61.12 | 66.21 | 71.30 | 76.39 | 81.49 | 86.58 | 91.67 | 96.77 | 101.86 | 106.95 | 112.05 | 117.14 | 122.23 | 127.32 | 152.79 | 183.35 | 213.90 |

| 50 | 1.35 | 1.47 | 1.58 | 1.70 | 1.82 | 1.93 | 2.05 | 2.17 | 2.27 | 2.37 | 2.46 | 2.56 | 2.66 | 2.75 | 3.21 | 3.75 | 4.27 |

| 100 | 2.71 | 2.94 | 3.17 | 3.40 | 3.63 | 3.87 | 4.11 | 4.35 | 4.54 | 4.74 | 4.93 | 5.12 | 5.31 | 5.50 | 6.42 | 7.50 | 8.54 |

| 200 | 4.91 | 5.32 | 5.73 | 6.15 | 6.57 | 6.99 | 7.42 | 7.85 | 8.20 | 8.54 | 8.89 | 9.22 | 9.56 | 9.89 | 11.52 | 13.41 | 15.23 |

| 300 | 6.91 | 7.48 | 8.06 | 8.64 | 9.23 | 9.83 | 10.43 | 11.04 | 11.52 | 12.00 | 12.47 | 12.94 | 13.41 | 13.87 | 16.12 | 18.71 | 21.20 |

| 400 | 8.77 | 9.50 | 10.23 | 10.98 | 11.73 | 12.48 | 13.25 | 14.02 | 14.63 | 15.23 | 15.82 | 16.41 | 16.99 | 17.57 | 20.38 | 23.62 | 26.72 |

| 500 | 10.53 | 11.40 | 12.29 | 13.18 | 14.08 | 14.99 | 15.92 | 16.85 | 17.57 | 18.28 | 18.99 | 19.69 | 20.38 | 21.07 | 24.40 | 28.22 | 31.88 |

| 600 | 12.20 | 13.22 | 14.24 | 15.28 | 16.33 | 17.39 | 18.46 | 19.55 | 20.38 | 21.20 | 22.02 | 22.82 | 23.62 | 24.40 | 28.22 | 32.59 | 36.76 |

| 700 | 13.80 | 14.95 | 16.11 | 17.29 | 18.48 | 19.69 | 20.91 | 22.15 | 23.09 | 24.01 | 24.92 | 25.82 | 26.72 | 27.60 | 31.88 | 36.76 | 41.39 |

| 800 | 15.32 | 16.61 | 17.91 | 19.23 | 20.56 | 21.91 | 23.28 | 24.66 | 25.70 | 26.72 | 27.72 | 28.72 | 29.70 | 30.68 | 35.39 | 40.74 | 45.81 |

| 900 | 16.79 | 18.21 | 19.64 | 21.09 | 22.56 | 24.05 | 25.56 | 27.10 | 28.22 | 29.34 | 30.44 | 31.52 | 32.59 | 33.65 | 38.77 | 44.57 | 50.04 |

| 1000 | 18.21 | 19.75 | 21.31 | 22.89 | 24.50 | 26.13 | 27.78 | 29.46 | 30.68 | 31.88 | 33.06 | 34.23 | 35.39 | 36.53 | 42.03 | 48.25 | 54.09 |

| 1100 | 19.57 | 21.24 | 22.92 | 24.56 | 26.38 | 28.14 | 29.94 | 31.76 | 33.06 | 34.35 | 35.62 | 36.87 | 38.10 | 39.32 | 45.19 | 51.80 | 57.98 |

| 1200 | 20.89 | 22.67 | 24.48 | 26.33 | 28.20 | 30.10 | 32.04 | 34.00 | 35.39 | 36.76 | 38.10 | 39.43 | 40.74 | 42.03 | 48.25 | 55.22 | 61.71 |

| 1300 | 22.16 | 24.06 | 26.00 | 27.97 | 29.97 | 32.01 | 34.08 | 36.19 | 37.66 | 39.10 | 40.52 | 41.93 | 43.31 | 44.67 | 51.21 | 58.52 | 65.29 |

| 1400 | 23.38 | 25.40 | 27.46 | 29.56 | 31.69 | 33.86 | 36.07 | 38.33 | 39.87 | 41.39 | 42.89 | 44.36 | 45.81 | 47.24 | 54.09 | 61.71 | 68.73 |

| 1500 | 24.57 | 26.71 | 28.88 | 31.10 | 33.37 | 35.67 | 38.02 | 40.41 | 42.03 | 43.62 | 45.19 | 46.73 | 48.25 | 49.74 | 56.88 | 64.79 | 72.03 |

| 1600 | 25.71 | 27.97 | 30.26 | 32.61 | 35.00 | 37.44 | 39.92 | 42.46 | 44.15 | 45.81 | 47.44 | 49.05 | 50.63 | 52.18 | 59.59 | 67.76 | 75.19 |

| 1700 | 26.82 | 29.19 | 31.60 | 34.07 | 36.59 | 39.16 | 41.78 | 44.46 | 46.22 | 47.95 | 49.64 | 51.31 | 52.95 | 54.56 | 62.23 | 70.63 | 78.22 |

| 1800 | 27.89 | 30.37 | 32.90 | 35.49 | 38.14 | 40.84 | 43.60 | 46.42 | 48.25 | 50.04 | 51.79 | 53.52 | 55.22 | 56.88 | 64.78 | 73.40 | 81.12 |

| 1900 | 28.92 | 31.51 | 34.16 | 36.87 | 39.65 | 42.48 | 45.38 | 48.35 | 50.23 | 52.08 | 53.90 | 55.68 | 57.43 | 59.15 | 67.27 | 76.07 | 83.89 |

| 2000 | 29.92 | 32.62 | 35.39 | 38.22 | 41.12 | 44.09 | 47.13 | 50.23 | 52.18 | 54.09 | 55.96 | 57.79 | 59.59 | 61.36 | 69.68 | 78.64 | 86.53 |

| 2100 | 30.89 | 33.70 | 36.57 | 39.53 | 42.55 | 45.65 | 48.83 | 52.08 | 54.09 | 56.05 | 57.97 | 59.86 | 61.71 | 63.51 | 72.03 | 81.12 | 89.05 |

| 2200 | 31.82 | 34.74 | 37.73 | 40.80 | 43.95 | 47.19 | 50.50 | 53.90 | 55.96 | 57.97 | 59.95 | 61.88 | 63.77 | 65.62 | 74.30 | 83.50 | 91.43 |

| 2300 | 32.72 | 35.74 | 38.85 | 42.04 | 45.32 | 48.68 | 52.14 | 55.68 | 57.79 | 59.86 | 61.88 | 63.85 | 65.79 | 67.68 | 76.51 | 85.79 | |

| 2400 | 33.59 | 36.72 | 39.93 | 43.25 | 46.65 | 50.15 | 53.74 | 57.43 | 59.59 | 61.71 | 63.77 | 65.79 | 67.76 | 69.68 | 78.64 | 87.98 | |

| 2500 | 34.42 | 37.66 | 40.99 | 44.42 | 47.19 | 51.58 | 55.31 | 59.15 | 61.36 | 63.51 | 65.62 | 67.68 | 69.68 | 71.64 | 80.72 | 90.08 | |

| 2600 | 35.23 | 38.57 | 42.01 | 45.56 | 48.68 | 52.98 | 56.85 | 60.83 | 63.09 | 65.29 | 67.43 | 69.52 | 71.56 | 73.55 | 82.72 | 92.09 | |

| 2700 | 36.00 | 39.44 | 43.00 | 46.67 | 50.15 | 54.34 | 58.36 | 62.48 | 64.78 | 67.02 | 69.21 | 71.33 | 73.40 | 75.41 | 84.66 | ||

| 2800 | 36.75 | 40.29 | 43.96 | 47.74 | 51.65 | 55.68 | 59.83 | 64.11 | 66.45 | 68.73 | 70.94 | 73.09 | 75.19 | 77.23 | 86.53 | ||

| 2900 | 37.46 | 41.11 | 44.89 | 48.79 | 52.82 | 56.99 | 61.28 | 65.70 | 68.08 | 70.39 | 72.64 | 74.82 | 76.94 | 78.99 | 88.34 | ||

| 3000 | 38.15 | 41.90 | 45.78 | 49.80 | 53.96 | 58.26 | 62.70 | 67.27 | 69.68 | 72.03 | 74.30 | 76.50 | 78.64 | 80.71 | 90.08 | ||

| 3200 | 39.44 | 43.39 | 47.49 | 51.75 | 56.16 | 60.72 | 65.44 | 70.31 | 72.79 | 75.19 | 77.51 | 79.76 | 81.93 | 84.02 | |||

| 3400 | 40.61 | 44.76 | 49.08 | 53.57 | 58.23 | 63.07 | 68.07 | 73.25 | 75.78 | 78.22 | 80.58 | 82.85 | 85.04 | 87.14 | |||

| 3600 | 41.67 | 46.02 | 50.55 | 55.28 | 60.19 | 65.30 | 70.59 | 76.07 | 78.64 | 81.12 | 83.50 | 85.79 | 87.98 | 90.08 | |||

| 3800 | 42.63 | 47.17 | 51.92 | 56.88 | 62.04 | 67.42 | 73.00 | 78.78 | 81.39 | 83.89 | 86.29 | 88.58 | 90.76 | ||||

| 4000 | 43.47 | 48.21 | 53.17 | 58.36 | 63.78 | 69.42 | 75.30 | 81.39 | 84.02 | 86.53 | 88.93 | 91.21 | |||||

| 4200 | 44.21 | 49.14 | 54.31 | 59.73 | 65.41 | 71.32 | 77.49 | 83.89 | 86.53 | 89.04 | 91.43 | ||||||

| 4400 | 44.85 | 49.96 | 55.35 | 61.00 | 66.92 | 73.11 | 79.57 | 86.29 | 88.93 | 91.43 | |||||||

| 4600 | 45.38 | 50.68 | 56.27 | 62.16 | 68.33 | 74.80 | 81.55 | 88.57 | 91.21 | ||||||||

| 4800 | 45.81 | 51.29 | 57.09 | 63.21 | 69.64 | 76.37 | 83.42 | 90.76 | |||||||||

| 5000 | 46.14 | 51.80 | 57.81 | 64.15 | 70.83 | 77.84 | 85.18 | ||||||||||

| 5200 | 46.36 | 52.20 | 58.41 | 64.99 | 71.92 | 79.20 | 86.84 | ||||||||||

| 5400 | 46.48 | 52.51 | 58.92 | 65.72 | 72.90 | 80.46 | |||||||||||

| 5600 | 46.51 | 52.70 | 59.32 | 68.34 | 73.78 | ||||||||||||

| 5800 | 46.43 | 52.80 | 59.61 | 66.86 | 74.54 | ||||||||||||

| 6000 | 46.25 | 52.79 | 59.80 | 67.28 | |||||||||||||

| y axis = revolution of the small tooth lock washer or pulley washer in min -1 | |||||||||||||||||

| Belt width b (mm) | 30 | 40 | 50 | 60 | 80 | 100 | 120 |

| Fupermissable (N) | 3436 | 4770 | 6152 | 7573 | 10513 | 13558 | 16690 |

| Width Factor BF | 0.21 | 0.29 | 0.37 | 0.45 | 0.63 | 0.81 | 1.00 |

| Teeth no. | 28 | 30 | 32 | 34 | 36 | 40 | 42 | 44 | 48 | 50 | 56 | 60 | 64 | 72 | 84 | ||

| dw | 124,8 | 133,7 | 142,6 | 151,5 | 160,4 | 178,3 | 187,1 | 196,1 | 214,0 | 222,8 | 249,6 | 267,4 | 285,2 | 320,9 | 374,3 | ||

| 20 | 3.07 | 3.34 | 3.61 | 3.80 | 4.00 | 4.38 | 4.57 | 4.75 | 5.12 | 5.31 | 5.85 | 6.21 | 6.56 | 7.26 | 8.27 | ||

| 40 | 6.15 | 6.67 | 7.22 | 7.61 | 7.99 | 8.76 | 9.13 | 9.51 | 10.25 | 10.62 | 11.70 | 12.42 | 13.12 | 14.51 | 16.55 | ||

| 60 | 9.22 | 10.01 | 10.82 | 11.41 | 11.99 | 13.13 | 13.70 | 14.26 | 15.37 | 15.92 | 17.55 | 18.62 | 19.68 | 21.77 | 24.82 | ||

| 80 | 12.29 | 13.35 | 14.43 | 15.21 | 15.98 | 17.51 | 18.27 | 19.02 | 20.50 | 21.23 | 23.41 | 24.83 | 26.25 | 29.03 | 33.10 | ||

| 90 | 13.83 | 15.02 | 16.23 | 17.11 | 17.98 | 19.70 | 20.55 | 21.39 | 23.06 | 23.89 | 26.33 | 27.94 | 29.53 | 32.65 | 37.24 | ||

| 100 | 15.36 | 16.68 | 18.04 | 19.01 | 19.98 | 21.89 | 22.83 | 23.77 | 25.62 | 26.54 | 29.26 | 31.04 | 32.81 | 36.28 | 41.37 | ||

| 200 | 27.88 | 30.31 | 32.81 | 34.55 | 36.28 | 39.69 | 41.37 | 43.04 | 46.34 | 47.97 | 52.79 | 55.95 | 59.07 | 65.20 | 74.16 | ||

| 300 | 39.25 | 42.74 | 46.34 | 48.78 | 51.19 | 55.95 | 58.29 | 60.62 | 65.20 | 67.47 | 74.16 | 78.54 | 82.86 | 91.35 | 103.71 | ||

| 400 | 49.84 | 54.38 | 59.07 | 62.15 | 65.20 | 71.20 | 74.16 | 77.09 | 82.86 | 85.71 | 94.13 | 99.63 | 105.06 | 115.69 | 131.15 | ||

| 500 | 59.83 | 65.42 | 71.20 | 74.89 | 78.54 | 85.71 | 89.24 | 92.74 | 99.63 | 103.03 | 113.05 | 119.60 | 126.05 | 138.68 | 157.02 | ||

| 600 | 69.31 | 75.96 | 82.86 | 87.13 | 91.34 | 99.63 | 103.70 | 107.74 | 115.68 | 119.60 | 131.15 | 138.68 | 146.10 | 160.61 | 181.65 | ||

| 700 | 78.36 | 86.09 | 94.13 | 98.95 | 103.70 | 113.05 | 117.65 | 122.19 | 131.15 | 135.56 | 148.55 | 157.02 | 165.36 | 181.65 | 205.24 | ||

| 800 | 87.02 | 95.84 | 105.05 | 110.40 | 115.68 | 126.05 | 131.14 | 136.18 | 146.10 | 150.98 | 165.36 | 174.73 | 183.94 | 201.93 | 227.94 | ||

| 900 | 95.32 | 105.27 | 115.68 | 121.54 | 127.33 | 138.68 | 144.25 | 149.77 | 160.61 | 165.95 | 181.65 | 191.88 | 201.93 | 221.54 | 249.87 | ||

| 1000 | 103.30 | 114.41 | 126.05 | 132.41 | 138.68 | 150.98 | 157.02 | 162.99 | 174.73 | 180.50 | 197.48 | 208.53 | 219.39 | 240.54 | 271.11 | ||

| 1100 | 110.98 | 123.27 | 136.18 | 143.02 | 149.76 | 162.99 | 169.47 | 175.88 | 188.49 | 194.68 | 212.90 | 224.75 | 236.38 | 259.05 | 291.72 | ||

| 1200 | 118.37 | 131.87 | 146.10 | 153.40 | 160.61 | 174.72 | 181.65 | 188.49 | 201.93 | 208.53 | 227.94 | 240.56 | 252.94 | 277.06 | 311.78 | ||

| 1300 | 125.49 | 140.24 | 155.82 | 163.58 | 171.23 | 186.21 | 193.56 | 200.82 | 215.07 | 222.07 | 242.64 | 256.00 | 269.11 | 294.62 | |||

| 1400 | 132.26 | 148.39 | 165.35 | 173.56 | 181.65 | 197.48 | 205.24 | 212.90 | 227.94 | 235.33 | 257.02 | 271.11 | 284.91 | 311.77 | |||

| 1500 | 138.98 | 156.32 | 174.72 | 183.36 | 191.87 | 208.53 | 216.69 | 224.75 | 240.56 | 248.32 | 271.10 | 285.89 | 300.38 | ||||

| 1600 | 145.36 | 164.06 | 183.93 | 193.00 | 201.92 | 219.39 | 227.94 | 236.38 | 252.94 | 261.07 | 284.91 | 300.38 | 315.53 | ||||

| 1700 | 151.51 | 171.60 | 193.00 | 202.48 | 211.81 | 230.06 | 238.99 | 247.81 | 265.10 | 273.59 | 298.46 | 314.59 | |||||

| 1800 | 157.44 | 178.96 | 201.92 | 211.81 | 221.53 | 240.56 | 249.87 | 259.05 | 277.05 | 285.89 | 311.77 | ||||||

| 1900 | 163.16 | 186.14 | 210.72 | 221.00 | 231.12 | 250.89 | 260.56 | 270.10 | 288.81 | 297.98 | 324.85 | ||||||

| 2000 | 168.67 | 193.16 | 219.38 | 230.06 | 240.56 | 261.07 | 271.10 | 280.99 | 300.38 | 309.88 | |||||||

| 2100 | 173.97 | 200.01 | 227.94 | 238.99 | 249.86 | 271.10 | 281.48 | 291.72 | 311.77 | 321.60 | |||||||

| 2200 | 179.08 | 206.69 | 236.37 | 247.80 | 259.04 | 280.99 | 291.72 | 302.29 | 322.99 | ||||||||

| 2300 | 183.99 | 213.23 | 244.71 | 256.51 | 268.10 | 290.75 | 301.81 | 312.71 | |||||||||

| 2400 | 188.71 | 219.61 | 252.94 | 265.10 | 277.05 | 300.38 | 311.77 | 322.99 | |||||||||

| 2500 | 193.24 | 225.85 | 261.07 | 273.58 | 285.88 | 309.88 | 321.60 | ||||||||||

| 2600 | 197.59 | 231.95 | 269.10 | 281.97 | 294.61 | 319.27 | |||||||||||

| 2700 | 201.76 | 237.90 | 277.05 | 290.26 | 303.24 | ||||||||||||

| 2800 | 205.75 | 243.72 | 284.91 | 298.46 | 311.76 | ||||||||||||

| 2900 | 209.57 | 249.41 | 292.68 | 306.56 | 320.20 | ||||||||||||

| 3000 | 213.21 | 254.96 | 300.37 | 314.58 | |||||||||||||

| 3100 | 216.68 | 260.39 | 307.98 | 322.52 | |||||||||||||

| 3200 | 219.99 | 265.69 | 315.52 | ||||||||||||||

| 3300 | 223.12 | 270.87 | 322.99 | ||||||||||||||

| 3400 | 226.09 | 275.92 | |||||||||||||||

| 3500 | 228.90 | 280.86 | |||||||||||||||

| y axis = revolution of the small tooth lock washer or pulley washer in min -1 | |||||||||||||||||

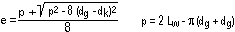

Running Round The Clock: load factors of the MEGATORQUE timing belt

Timing belts transmit tensile strength without slipping with the result that the greatest longitudinal force or pull determines the width of the belt. With drives where operating conditions are characterised by jerky movements and impact, it is recommended to take a load factor of c2 = 2.0.

| Service factor c0 = c2 + c3 | |||||||||

| Load factor c2 | Examples of drive units | ||||||||

| Electric motors with low starting torque (up to 1.5 x nominal torque) e.g. DC shunt motors, combustion engines with 8 or more cylinders, water and steam turbines | Three-phase and AC motors with normal starting torque (1.5-2.5 x nominal torque) e.g. DC shunt motors with compound winding, squirrel cage motors, combustion engines with 4-6 cylinders | Three-phase and AC motors with high starting and brake torque (exceeding 2.5 x nominal torque) e.g. single phase and synchronous motors with high torque, combustion engines up to 4 cylinders | |||||||

| Example of working machines |

Load factor c2 for daily operating time (hours) | ||||||||

| up to 10 |

10 up to 16 |

over 16 |

up to 10 | 10 up to 16 |

over 16 |

up to 10 |

10 up to 16 |

over 16 |

|

| Belt conveyors, measuring instruments, medical equipment |

1.1 | 1.3 | 1.5 | 1.2 | 1.4 | 1.6 | 1.3 | 1.5 | 1.7 |

| Tooling machinery, (lightweight turning machines), woodworking machines (circular saws, belt saws, planing machines), textile machines (bobbin winding machines, wrapping machines), paper industry machinery (calanders, dryers, drum strainers), dough mixers, laundry machines |

1.2 | 1.4 | 1.6 | 1.4 | 1.6 | 1.8 | 1.6 | 1.8 | 2.0 |

| Fans up to 10 kW, textile machinery (spinning, weaving and twisting), tooling machines, (rolling machines, grinding machines and planing machines, lightweight milling machines), stirrers and mixers for semi-liquid products |

1.3 | 1.5 | 1.7 | 1.5 | 1.7 | 1.9 | 1.7 | 1.9 | 2.1 |

| Fans (radial blowers), compressors (radial compressors), paper machines, rotary pumps, gear pumps and centrifugal pumps, Jordan pumps, belt conveyor systems for ores and coal, pit fans, heavy textile machinery, elevators, generators, excoter machines | 1.4 | 1.6 | 1.8 | 1.6 | 1.8 | 2.0 | 1.8 | 2.0 | 2.2 |

| Piston machines, pumps, compressors, rolling crushers, shredders, kneading machines, fans, paper mills, defibrators | 1.6 | 1.8 | 2.0 | 1.8 | 2.0 | 2.2 | 2.0 | 2.2 | 2.4 |

| Acceleration factor c3 | ||

| Transmission ratio | Acceleration factor | |

| i | c3 | |

| 1 up to 1,24 | 0.00 | |

| 1,25 up to 1,74 | 0.10 | |

| 1,75 up to 2,49 | 0.20 | |

| 2,50 up to 3,49 | 0.30 | |

| over 3,5 | 0.40 | |

| Correction factor 3M | |||||||||||||

| Belt length (mm) |

bis 189 | 189-261 | 261-402 | 402-600 | >600 | ||||||||

| Correction factor | 0.79 | 0.87 | 1.00 | 1.08 | 1.18 | ||||||||

| Correction factor 5M | |||||||||||||

| Belt length (mm) |

bis 189 | 189-261 | 261-402 | 402-600 | >600 | ||||||||

| Correction factor | 0.79 | 0.87 | 1.00 | 1.08 | 1.18 | ||||||||

| Correction factor 8M | |||||||||||||

| Belt length (mm) |

640 | 720 | 800 | 896 | 1000 | 1120 | 1200 | 1280 | 1440 | 1600 | 1792 | 2000 | |

| Correction factor | 0.79 | 0.83 | 0.87 | 0.91 | 0.96 | 1.00 | 1.03 | 1.05 | 1.10 | 1.14 | 1.18 | 1.22 | |

| Belt length (mm) |

2240 | 2400 | 2520 | 2600 | 2800 | 2840 | 3048 | 3200 | 3600 | 4000 | 4400 | 4480 | |

| Correction factor | 1.26 | 1.29 | 1.31 | 1.32 | 1.35 | 1.36 | 1.38 | 1.40 | 1.45 | 1.49 | 1.52 | 1.53 | |

| Correction factor 14M | |||||||||||||

| Belt length (mm) |

994 | 1120 | 1190 | 1260 | 1400 | 1568 | 1610 | 1750 | 1960 | 2100 | 2240 | 2310 | 2380 |

| Correction factor | 0.68 | 0.73 | 0.75 | 0.77 | 0.81 | 0.85 | 0.86 | 0.89 | 0.94 | 0.96 | 0.99 | 1.00 | 1.01 |

| Belt length (mm) |

2450 | 2520 | 2590 | 2660 | 2800 | 3136 | 3304 | 3360 | 3500 | 3850 | 3920 | 1326 | 4410 |

| Correction factor | 1.02 | 1.03 | 1.04 | 1.05 | 1.07 | 1.12 | 1.14 | 1.14 | 1.16 | 1.19 | 1.20 | 1.24 | 1.25 |