Synchro-Star-Belts

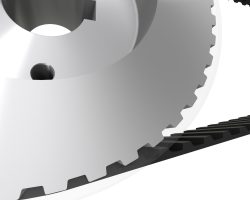

This standard timing belt was developed so as to round off the product range for our clients. It is viewed as a particularly favourably priced solution, which does the job of transmitting power using a timing belt.

- Technical Details

- Belt Sizes

- Standard Tooth Lock Washers

- Special Tooth Lock Washers

- Installation and Mounting

Advantages

- This belt designed for toothed power transmission solves the problems linked with chains and cogwheels. Especially those types displaying the extra short distance lend themselves for use with precision instruments and IT systems.

- Thin, lightweight and fantastically flexible - this belt is ideal for compactly-designed applications

- Highly efficient, top-speed transmission

- Less operating noise when compared with chains/cogwheels

- Maintenance-free

- Standard belts can be used with temperatures ranging between -30°C and +80°C and they also provide a great deal of muscle with their conductive properties

| Material | Chloroprene |

| Standard tensile member | Carbon |

| Timing belt profile | MXL, XL, L, H, XH, XXH |

| Tooth lock washer profile | Standard |

| Double toothed | yes |

| Coating | Nylon |

| Temperature range | -30° - +80° Celsius |

| Oil resistance | normal |

| Wear resistant | good |

| electrical conductivity | ISO 9563 |

| Model | t | ht | hS |

| MXL | 2.032 | 0.510 | 1.110 |

| DMXL | 2.032 | 0.510 | 1.530 |

| XL | 5.080 | 1.270 | 2.270 |

| DXL | 5.080 | 1.270 | 3.050 |

| L | 9.525 | 1.910 | 3.610 |

| DL | 9.525 | 1.910 | 4.580 |

| H | 12.700 | 2.290 | 4.590 |

| DH | 12.700 | 2.290 | 5.950 |

| XH | 22.225 | 6.350 | 11.200 |

| XXH | 31.750 | 9.530 | 15.700 |

Synchro-Star Order Reference

| Belt type | MXL | ||

| Tooth distance | 2,032 (mm) | ||

| Width code | 013 / 019 / 025 / 037 / 050 | ||

| Width in mm | 3,2 / 4,8 / 6,4 / 9,5 / 12,7 | ||

| Size | 34 MXL | 126 MXL | 365 (D)MXL |

| 35 MXL | 127 MXL | 372 (D)MXL | |

| 40 MXL | 128 MXL | 380 (D)MXL | |

| 41 MXL | 129 MXL | 397 (D)MXL | |

| 45 MXL | 130 MXL | 400 (D)MXL | |

| 48 MXL | 131 MXL | 405 (D)MXL | |

| 50 MXL | 132 MXL | 419 (D)MXL | |

| 52 MXL | 135 MXL | 424 (D)MXL | |

| 53 MXL | 138 MXL | 435 (D)MXL | |

| 54 MXL | 140 MXL | 436 (D)MXL | |

| 55 MXL | 144 MXL | 448 (D)MXL | |

| 56 MXL | 147 (D)MXL | 453 (D)MXL | |

| 59 MXL | 150 (D)MXL | 464 (D)MXL | |

| 60 MXL | 155 (D)MXL | 478 (D)MXL | |

| 63 MXL | 158 (D)MXL | 498 (D)MXL | |

| 65 MXL | 160 (D)MXL | 503 (D)MXL | |

| 67 MXL | 165 (D)MXL | 515 (D)MXL | |

| 68 MXL | 170 (D)MXL | 520 (D)MXL | |

| 70 MXL | 175 (D)MXL | 537 (D)MXL | |

| 71 MXL | 180 (D)MXL | 550 (D)MXL | |

| 72 MXL | 184 (D)MXL | 569 (D)MXL | |

| 73 MXL | 185 (D)MXL | 591 (D)MXL | |

| 75 MXL | 187 (D)MXL | 650 (D)MXL | |

| 76 MXL | 190 (D)MXL | 705 (D)MXL | |

| 78 MXL | 195 (D)MXL | 772 (D)MXL | |

| 79 MXL | 200 (D)MXL | 1369 MXL | |

| 80 MXL | 203 (D)MXL | ||

| 81 MXL | 205 (D)MXL | ||

| 82 MXL | 210 (D)MXL | ||

| 83 MXL | 212 (D)MXL | ||

| 85 MXL | 219 (D)MXL | ||

| 87 MXL | 220 (D)MXL | ||

| 88 MXL | 224 (D)MXL | ||

| 89 MXL | 227 (D)MXL | ||

| 90 MXL | 228 (D)MXL | ||

| 91 MXL | 232 (D)MXL | ||

| 92 MXL | 236 (D)MXL | ||

| 93 MXL | 239 (D)MXL | ||

| 94 MXL | 240 (D)MXL | ||

| 95 MXL | 250 (D)MXL | ||

| 97 MXL | 256 (D)MXL | ||

| 98 MXL | 260 (D)MXL | ||

| 100 MXL | 265 (D)MXL | ||

| 102 MXL | 280 (D)MXL | ||

| 103 MXL | 281 (D)MXL | ||

| 105 MXL | 290 (D)MXL | ||

| 106 MXL | 295 (D)MXL | ||

| 110 MXL | 300 (D)MXL | ||

| 112 MXL | 310 (D)MXL | ||

| 114 MXL | 312 (D)MXL | ||

| 115 MXL | 315 (D)MXL | ||

| 118 MXL | 324 (D)MXL | ||

| 120 MXL | 332 (D)MXL | ||

| 121 MXL | 336 (D)MXL | ||

| 122 MXL | 338 (D)MXL | ||

| 123 MXL | 339 (D)MXL | ||

| 125 MXL | 350 (D)MXL | ||

| Calculation formula | Teeth no. = Length code | ||

| Calculation of the belt pitch length in mm | |||

| Teeth no. x tooth distance (2,032 mm) | |||

| Example: 34MXL: 34x2,032 = 69,09 mm | |||

| Belt type | XL | ||

| Tooth distance | 5,08 (mm) | ||

| Width code | 025 / 031 / 037 / 050 | ||

| Width in mm | 6,4 / 7,9 / 9,5 / 12,7 | ||

| Size | 60 XL | 180 (D)XL | 490 (D)XL |

| 64 XL | 182 (D)XL | 522 XL | |

| 68 XL | 184 (D)XL | 532 XL | |

| 70 XL | 186 (D)XL | 564 XL | |

| 76 XL | 188 (D)XL | 592 XL | |

| 78 XL | 190 (D)XL | 600 XL | |

| 80 XL | 192 (D)XL | 616 XL | |

| 81 XL | 194 (D)XL | 630 XL | |

| 84 XL | 196 (D)XL | 670 XL | |

| 86 XL | 198 (D)XL | 754 XL | |

| 88 XL | 200 (D)XL | 828 XL | |

| 90 XL | 202 (D)XL | 860 XL | |

| 92 XL | 204 (D)XL | ||

| 94 XL | 206 (D)XL | ||

| 96 XL | 210 (D)XL | ||

| 98 XL | 212 (D)XL | ||

| 100 XL | 216 (D)XL | ||

| 102 XL | 218 (D)XL | ||

| 104 XL | 220 (D)XL | ||

| 108 XL | 228 (D)XL | ||

| 110 XL | 230 (D)XL | ||

| 112 XL | 234 (D)XL | ||

| 114 XL | 236 (D)XL | ||

| 116 XL | 240 (D)XL | ||

| 118 XL | 250 (D)XL | ||

| 120 XL | 254 (D)XL | ||

| 122 XL | 260 (D)XL | ||

| 124 XL | 270 (D)XL | ||

| 126 XL | 276 (D)XL | ||

| 128 XL | 280 (D)XL | ||

| 130 XL | 282 (D)XL | ||

| 134 XL | 290 (D)XL | ||

| 136 XL | 300 (D)XL | ||

| 138 XL | 310 (D)XL | ||

| 140 XL | 314 XL | ||

| 142 XL | 320 (D)XL | ||

| 144 XL | 330 (D)XL | ||

| 146 XL | 332 (D)XL | ||

| 148 XL | 340 (D)XL | ||

| 150 (D)XL | 348 (D)XL | ||

| 152 (D)XL | 352 (D)XL | ||

| 154 (D)XL | 360 (D)XL | ||

| 156 (D)XL | 370 (D)XL | ||

| 158 (D)XL | 376 (D)XL | ||

| 160 (D)XL | 384 (D)XL | ||

| 162 (D)XL | 388 (D)XL | ||

| 164 (D)XL | 390 (D)XL | ||

| 166 (D)XL | 396 (D)XL | ||

| 170 (D)XL | 414 (D)XL | ||

| 172 (D)XL | 424 (D)XL | ||

| 174 (D)XL | 460 (D)XL | ||

| 176 (D)XL | 478 (D)XL | ||

| 178 (D)XL | 480 (D)XL | ||

| Calculation formula | Teeth no. = Length code/2 | ||

| Calculation of the belt pitch length in mm | |||

| (Zahl der Zähne/2) x tooth distance (5,08 mm) | |||

| Example: 60XL: (60/2)x5,08 = 152,40 mm | |||

| Belt type | L | ||

| Tooth distance | 9,525 (mm) | ||

| Width code | 050 / 075 / 100 / 150 | ||

| Width in mm | 12,7 / 19,1 / 25,4 / 38,1 | ||

| Size | 109 L | 124 L | 135 L |

| 150 L | 165 L | 173 L | |

| 187 (D)L | 210 L | 217 L | |

| 225 (D)L | 232 (D)L | 240 L | |

| 255 (D)L | 265 (D)L | 270 (D)L | |

| 277 (D)L | 285 (D)L | 300 (D)L | |

| 320 (D)L | 322 (D)L | 334 (D)L | |

| 337 (D)L | 345 (D)L | 360 (D)L | |

| 367 (D)L | 375 (D)L | 382 (D)L | |

| 390 (D)L | 394 (D)L | 398 (D)L | |

| 420 (D)L | 427 (D)L | 435 (D)L | |

| 450 (D)L | 454 (D)L | 480 (D)L | |

| 510 (D)L | 525 (D)L | 540 (D)L | |

| 548 (D)L | 581 (D)L | 600 (D)L | |

| 630 (D)L | 653 (D)L | 660 L | |

| 697 L | 731 L | 934 L | |

| Calculation formula | Teeth no. = Length code/3,75 (round on full teeth) | ||

| Calculation of the belt pitch length in mm | |||

| (Zahl der Zähne/3,75 rounded) x tooth distance (9,525 mm) | |||

| Example: 109L: (109/3,75) = 29 Tooth 29x9,525= 276,23 mm |

|||

| Belt type | H | ||

| Tooth distance | 12,7 (mm) | ||

| Width code | 075 / 100 / 150 / 200 /300 | ||

| Width in mm | 19,1 / 25,4 / 38,1 /50,8 /76,2 | ||

| Size | 225 H | 570 (D)H | |

| 230 H | 600 (D)H | ||

| 240 (D)H | 625 (D)H | ||

| 245 (D)H | 630 (D)H | ||

| 255 (D)H | 650 (D)H | ||

| 270 (D)H | 660 (D)H | ||

| 280 (D)H | 680 (D)H | ||

| 300 (D)H | 700 (D)H | ||

| 310 (D)H | 750 (D)H | ||

| 315 (D)H | 770 (D)H | ||

| 320 (D)H | 800 (D)H | ||

| 330 (D)H | 810 (D)H | ||

| 350 (D)H | 840 (D)H | ||

| 360 (D)H | 850 (D)H | ||

| 370 (D)H | 860 (D)H | ||

| 375 (D)H | 880 (D)H | ||

| 390 (D)H | 900 (D)H | ||

| 400 (D)H | 950 (D)H | ||

| 410 (D)H | 1000 (D)H | ||

| 420 (D)H | 1100 (D)H | ||

| 430 (D)H | 1120 (D)H | ||

| 450 (D)H | 1130 (D)H | ||

| 465 (D)H | 1245 (D)H | ||

| 480 (D)H | 1250 (D)H | ||

| 490 H | 1360 H | ||

| 510 (D)H | 1400 (D)H | ||

| 530 (D)H | 1700 (D)H | ||

| 540 (D)H | 1765 (D)H | ||

| 560 (D)H | |||

| Calculation formula | Teeth no. = Length code/5 | ||

| Calculation of the belt pitch length in mm | |||

| Zahl der Zähne/5 x tooth distance (12,7 mm) | |||

| Example: 225H: (225/5)x12,7 = 571,5 mm | |||

| Belt type | XH |

| Tooth distance | 22,225 mm |

| Width code | 200 / 300 / 400 /500 / 600 |

| Width in mm | 50,8 / 76,2 / 101,6 /127 / 152,4 |

| Size | 463 XH |

| 507 XH | |

| 560 XH | |

| 630 XH | |

| 700 XH | |

| 735 XH | |

| 770 XH | |

| 840 XH | |

| 927 XH | |

| 980 XH | |

| 1120 XH | |

| 1260 XH | |

| 1400 XH | |

| 1540 XH | |

| 1750 XH | |

| Calculation formula | Teeth no. = Length code/8,74 (round on full teeth) |

| Calculation of the belt pitch length in mm | |

| (Zahl der Zähne/8,74 rounded) x tooth distance (22,225 mm) | |

| Example: 463XH: (463/8,74) = 53 Zähne 53x22,225= 1.177,93 mm |

| Belt type | XXH |

| Tooth distance | 31,75 mm |

| Width code | 200 / 300 / 400 /500 / 600 |

| Width in mm | 50,8 / 76,2 / 101,6 /127 / 152,4 |

| Size | 700 XXH |

| 800 XXH | |

| 900 XXH | |

| 1000 XXH | |

| 1200 XXH | |

| 1400 XXH | |

| 1600 XXH | |

| 1800 XXH | |

| Calculation formula | Teeth no. = Length code/12,5 |

| Calculation of the belt pitch length in mm | |

| (Zahl der Zähne/12,5) x tooth distance (31,75 mm) | |

| Example: 700XXH: (700/12,5)x31,75 = 1.778 mm |

An impressively extensive range of tooth lock washers for the pitches of MXL, XL, L and H is also available. These can be delivered pre-drilled or in the taper lock version.

Contact us and tell us exactly what you need.

Alongside our wide standard range of this product, we also craft in our ateliers high-precision drawing parts and customised special pulley washers for MXL, XL, L, H and XH pitches. With all our products we offer a comprehensive service ranging from the manufacturing of mechanical processing parts and gearing components right up to the mounting of finished systems and assembly units.

In order to achieve optimal performance and as long a service life as possible, timing belts have to be correctly installed, correctly tightened and correctly aligned. Prior to installation, it is always recommendable to inspect the belts for any possible damage resulting from transport or storage.

The Correct Mounting

Pulleys and, of course, belts themselves always have to be mounted with the correct alignment. This means that belts cannot be bent or buckled in any way, which could lead to a drop below the minimum permissible pulley diameter. That corresponds to approximately 50 mm for belts with a pitch of 8 mm and about 125 mm for those belts with a 14 mm pitch. Imbalanced drives cause a variety of belt tension problems and edge stresses and are also responsible for extreme lateral movement, the undesired wobble. All this leads to increased operating noise and more wear and tear on the belt. Therefore the parallelism error of the pulleys should only amount to a maximum of 0.5% of the centre distance. Angle accuracy is to be maintained by keeping misalignment down to 0.25° at the very most.

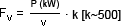

Pre-Tensioning The Belt Correctly

Firstly the belt always has to be tightened in line with the calculated pre-tensioning force and checked after a running-in period of about 5 minutes. The belt is then to be retightened according to the relevant value, should it have shifted or altered its position in any way. Finally after a further 8 hours of operating, the belt is to be once again inspected and, if necessary, tightened to comply with the required value that has already been calculated.

Causes of failure and corrective measures can be found in the following document:

Troubleshooting for power transmission products

| Belt length mm |

Minimal adjustment for installation |

Required adjustment range for tightening |

||||

| MXL | XL | L | H | XH | MXL,XL,L,H,XH | |

| smaller than 1525 | 15,5 mm | 20,5 mm | 34,5 mm | 59,5 mm | 79,5 mm | 2,5 mm |

| 1525-3050 | 18 mm | 23 mm | 37 mm | 62 mm | 82 mm | 5 mm |

| greater than 3050 | 20,5 mm | 25,5 mm | 39,5 mm | 64,5 mm | 84,5 mm | 7,5 mm |

| Adjustment range for XXH can be requested if needed | ||||||