Synchrobelt STD

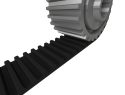

Supertorque belts, 8 pitch, round off the Synchrobelt range of timing belts and these also enable the implementation of this profile type in conjunction with the ContiTech company.

Advantages

The belt is on offer in a variety of tooth shapes (MXL-XXH / HTD / STD) and lends itself for use in the lower and medium power range.

1. Partially oil resistant

2. These belts can be operated within a temperature range of -20°C up to +100°C

3. They are suitable for tropical conditions, are ageing resistant and also ozone resistant

4. Such belts can be used with inner and outer idler pulleys

5. Maintenance-free

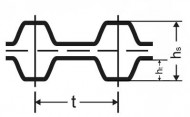

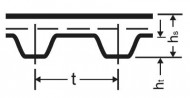

| S8M | DS8M | |

| Tooth pitch t (mm) | 8.00 | 8.00 |

| Belt thickness hs(mm) | 5.30 | 7.30 |

| Tooth height ht (mm) | 2.95 | 3.00 |

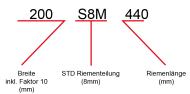

Order Reference

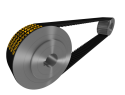

For double-toothed timing belts the order reference is, for example, DS8M.

| Description | Length (mm) | 8M Belt width code (mm) | |

| S 8M 440 | 440 | ||

| S 8M 464 | 464 | 20 | |

| S 8M 480 | 480 | 30 | |

| S 8M 528 | 528 | 50 | |

| S 8M 560 | 560 | 85 | |

| S 8M 600 | 600 | SLEEVE | |

| S 8M 632 | 632 | ||

| S 8M 640 | 640 | ||

| S 8M 656 | 656 | ||

| S 8M 672 | 672 | ||

| S 8M 688 | 688 | ||

| S 8M 696 | 696 | ||

| S 8M 712 | 712 | ||

| S 8M 720 | 720 | ||

| S 8M 728 | 728 | ||

| S 8M 736 | 736 | ||

| S 8M 760 | 760 | ||

| S 8M 768 | 768 | ||

| S 8M 784 | 784 | ||

| S 8M 792 | 792 | ||

| S 8M 800 | 800 | ||

| S 8M 824 | 824 | ||

| S 8M 840 | 840 | ||

| S 8M 848 | 848 | ||

| S 8M 864 | 864 | ||

| S 8M 880 | 880 | ||

| S 8M 896 | 896 | ||

| S 8M 912 | 912 | ||

| S 8M 920 | 920 | ||

| S 8M 944 | 944 | ||

| S 8M 960 | 960 | ||

| S 8M 992 | 992 | ||

| S 8M 1000 | 1000 | ||

| S 8M 1024 | 1024 | ||

| S 8M 1032 | 1032 | ||

| S 8M 1056 | 1056 | ||

| S 8M 1064 | 1064 | ||

| S 8M 1072 | 1072 | ||

| S 8M 1080 | 1080 | ||

| S 8M 1096 | 1096 | ||

| S 8M 1120 | 1120 | ||

| S 8M 1136 | 1136 | ||

| S 8M 1152 | 1152 | ||

| S 8M 1160 | 1160 | ||

| S 8M 1168 | 1168 | ||

| S 8M 1176 | 1176 | ||

| S 8M 1184 | 1184 | ||

| S 8M 1192 | 1192 | ||

| S 8M 1200 | 1200 | ||

| S 8M 1208 | 1208 | ||

| S 8M 1216 | 1216 | ||

| S 8M 1240 | 1240 | ||

| S 8M 1256 | 1256 | ||

| S 8M 1264 | 1264 | ||

| S 8M 1280 | 1280 | ||

| S 8M 1296 | 1296 | ||

| S 8M 1304 | 1304 | ||

| S 8M 1312 | 1312 | ||

| S 8M 1344 | 1344 | ||

| S 8M 1352 | 1352 | ||

| S 8M 1368 | 1368 | ||

| S 8M 1400 | 1400 | ||

| S 8M 1408 | 1408 | ||

| S 8M 1440 | 1440 | ||

| S 8M 1480 | 1480 | ||

| S 8M 1512 | 1512 | ||

| S 8M 1520 | 1520 | ||

| S 8M 1552 | 1552 | ||

| S 8M 1600 | 1600 | ||

| S 8M 1624 | 1624 | ||

| S 8M 1760 | 1760 | ||

| S 8M 1776 | 1776 | ||

| S 8M 1800 | 1800 | ||

| S 8M 1816 | 1816 | ||

| S 8M 1912 | 1912 | ||

| S 8M 2000 | 2000 | ||

| S 8M 2240 | 2240 | ||

| S 8M 2272 | 2272 | ||

| S 8M 2392 | 2392 | ||

| S 8M 2800 | 2800 | ||

| S 8M 2848 | 2848 |

| Description | Length (mm) | 8M Belt width code (mm) | |

| DS 8M 656 | 656 | 20 | |

| DS 8M 720 | 720 | 30 | |

| DS 8M 760 | 760 | 50 | |

| DS 8M 800 | 800 | 85 | |

| DS 8M 848 | 848 | SLEEVE | |

| DS 8M 880 | 880 | ||

| DS 8M 960 | 960 | ||

| DS 8M 1000 | 1000 | ||

| DS 8M 1056 | 1056 | ||

| DS 8M 1064 | 1064 | ||

| DS 8M 1072 | 1072 | ||

| DS 8M 1120 | 1120 | ||

| DS 8M 1136 | 1136 | ||

| DS 8M 1160 | 1160 | ||

| DS 8M 1168 | 1168 | ||

| DS 8M 1176 | 1176 | ||

| DS 8M 1184 | 1184 | ||

| DS 8M 1200 | 1200 | ||

| DS 8M 1216 | 1216 | ||

| DS 8M 1240 | 1240 | ||

| DS 8M 1264 | 1264 | ||

| DS 8M 1280 | 1280 | ||

| DS 8M 1296 | 1296 | ||

| DS 8M 1304 | 1304 | ||

| DS 8M 1344 | 1344 | ||

| DS 8M 1368 | 1368 | ||

| DS 8M 1400 | 1400 | ||

| DS 8M 1408 | 1408 | ||

| DS 8M 1440 | 1440 | ||

| DS 8M 1480 | 1480 | ||

| DS 8M 1512 | 1512 | ||

| DS 8M 1552 | 1552 | ||

| DS 8M 1600 | 1600 | ||

| DS 8M 1624 | 1624 | ||

| DS 8M 1760 | 1760 | ||

| DS 8M 1776 | 1776 | ||

| DS 8M 1800 | 1800 | ||

| DS 8M 1912 | 1912 | ||

| DS 8M 2000 | 2000 | ||

| DS 8M 2240 | 2240 | ||

| DS 8M 2392 | 2392 |

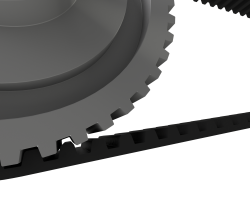

Gap Profile of Tooth Lock Washers

It is imperative that the gaps between the teeth of the washers making up the SuperTorque timing belt correspond exactly to the pitch and that they are manufactured according to the recommended range of tolerance. Only by adhering to the specified dimensions can utmost strength and smooth running with virtually no signs of play be guaranteed for the SuperTorque timing belt.

Tooth Lock Washers - The Materials

The most diverse types of materials, such as sintered metal, plastics, aluminium, steel, grey cast iron and cast steel, can be used to make tooth lock washers. But the material is primarily chosen so as to best suit the intended use and the demands in question, whereby particular attention should be paid to ensuring that adequate resistance to wear is present. In the case of substantial series production requirements, manufacturing tooth lock washers using the full mould process (injection moulding or pressure die-casting) is the most appropriate method.

Flanged Wheels

Flanged wheels or pulleys prevent the wearing down of timing belts. It is necessary that at least one of the tooth lock washers - for cost reasons usually the smaller one - is fitted with 2 flanged wheels. The mounting of 1 flanged wheel on both sides of each tooth lock washer is also possible. With drives having a centre distance greater than 8 times dw, it is recommendable to attach 2 flanged wheels per tooth lock washer.

Parallelism

The teeth should run parallel to the axis of the borehole with a maximum deviation of 0.001 mm per millimetre of the width.

Conicity

The conicity can only amount to a maximum of 0.001 mm per millimetre in the head width and, at the same time, is not to exceed the permissible diameter tolerance.

Surface Quality in accordance with ISO R 46

The surface quality is not to exceed the value of Ra=3,2 µm for tooth flanks and tooth crest.

Balancing

With tooth lock washers that are processed on both sides, balancing is usually not necessary up to a peripheral velocity of 30 m/s. But cast discs are even to be balanced at v < 30 m/s.

The following is a general rule of thumb:

- Balancing in one plane, quality level Q 16 in accordance with VDI 2060 at v = 30 m/s for dw>400 mm or at n = 1500 min-1 for dw 400 mm.

- Balancing on two planes with the recommendation Q 6.3 at v > 30 m/s or at v> 20 m/s at a ratio of effective diameter to tooth lock washer width < 4.

Balancing is carried out on ungrooved tooth lock washers by means of a smooth balancing mandrel.

Further details can be found in ISO 254 and in the VDI Guideline 2060.

| Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) |

| 12 | 17,19 | 16,43 | 42 | 60,16 | 59,40 | 72 | 103,13 | 102,37 |

| 13 | 18,62 | 17,86 | 43 | 61,59 | 60,83 | 73 | 104,56 | 103,80 |

| 14 | 20,05 | 19,29 | 44 | 63,03 | 62,26 | 74 | 106,00 | 105,24 |

| 15 | 21,49 | 20,72 | 45 | 64,46 | 63,70 | 75 | 107,43 | 106,67 |

| 16 | 22,92 | 22,16 | 46 | 65,89 | 65,13 | 76 | 108,86 | 108,10 |

| 17 | 24,35 | 23,59 | 47 | 67,32 | 66,56 | 77 | 110,29 | 109,53 |

| 18 | 25,78 | 25,02 | 48 | 68,75 | 67,99 | 78 | 111,73 | 110,96 |

| 19 | 27,22 | 26,45 | 49 | 70,19 | 69,43 | 79 | 113,16 | 112,40 |

| 20 | 28,65 | 27,89 | 50 | 71,62 | 70,86 | 80 | 114,59 | 113,83 |

| 21 | 30,08 | 29,32 | 51 | 73,05 | 72,29 | 81 | 116,02 | 115,26 |

| 22 | 31,51 | 30,75 | 52 | 74,48 | 73,72 | 82 | 117,46 | 116,69 |

| 23 | 32,95 | 32,18 | 53 | 75,92 | 75,15 | 93 | 118,89 | 118,13 |

| 24 | 34,38 | 33,62 | 54 | 77,35 | 76,59 | 84 | 120,32 | 119,56 |

| 25 | 35,81 | 35,05 | 55 | 78,78 | 78,02 | 85 | 121,75 | 120,99 |

| 26 | 37,24 | 36,48 | 56 | 80,21 | 79,45 | 86 | 123,19 | 122,42 |

| 27 | 38,67 | 37,91 | 57 | 81,65 | 80,88 | 87 | 124,62 | 123,86 |

| 28 | 40,11 | 39,35 | 58 | 83,08 | 82,32 | 88 | 126,05 | 125,29 |

| 29 | 41,54 | 40,78 | 59 | 84,51 | 83,75 | 89 | 127,48 | 126,72 |

| 30 | 42,97 | 42,21 | 60 | 85,94 | 85,18 | 90 | 128,92 | 128,15 |

| 31 | 44,40 | 43,64 | 61 | 87,38 | 86,61 | 91 | 130,35 | 129,59 |

| 32 | 45,84 | 45,07 | 62 | 88,81 | 88,05 | 92 | 131,78 | 131,02 |

| 33 | 47,27 | 46,51 | 63 | 90,24 | 89,48 | 93 | 133,21 | 132,45 |

| 34 | 48,70 | 47,94 | 64 | 91,67 | 90,91 | 94 | 134,65 | 133,88 |

| 35 | 50,13 | 49,37 | 65 | 93,11 | 92,34 | 95 | 136,08 | 135,32 |

| 36 | 51,57 | 50,80 | 66 | 94,54 | 93,78 | 96 | 137,51 | 136,75 |

| 37 | 53,00 | 52,24 | 67 | 95,97 | 95,21 | 97 | 138,94 | 138,18 |

| 38 | 54,43 | 53,67 | 68 | 97,40 | 96,64 | 98 | 140,37 | 139,61 |

| 39 | 55,86 | 55,10 | 69 | 98,84 | 98,07 | 99 | 141,81 | 141,05 |

| 40 | 57,30 | 56,53 | 70 | 100,27 | 99,51 | 100 | 143,24 | 142,48 |

| 41 | 58,73 | 57,97 | 71 | 101,70 | 100,94 |

| Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) |

| 18 | 45,84 | 44,46 | 61 | 155,34 | 153,96 | 104 | 264,83 | 263,46 |

| 19 | 48,38 | 47,01 | 62 | 157,88 | 156,51 | 105 | 267,38 | 266,01 |

| 20 | 50,39 | 49,56 | 63 | 160,43 | 159,06 | 106 | 269,93 | 268,55 |

| 21 | 53,48 | 52,10 | 64 | 162,97 | 161,60 | 107 | 272,47 | 271,10 |

| 22 | 56,02 | 54,65 | 65 | 165,52 | 164,15 | 108 | 275,02 | 273,65 |

| 23 | 58,57 | 57,20 | 66 | 168,07 | 166,70 | 109 | 277,57 | 276,19 |

| 24 | 61,12 | 59,74 | 67 | 170,61 | 169,24 | 110 | 280,11 | 278,74 |

| 25 | 63,66 | 62,29 | 68 | 173,16 | 171,79 | 11 | 282,66 | 281,29 |

| 26 | 66,21 | 64,84 | 69 | 175,71 | 174,34 | 112 | 285,21 | 283,83 |

| 27 | 68,75 | 67,38 | 70 | 178,25 | 176,88 | 113 | 287,75 | 286,38 |

| 28 | 71,30 | 69,93 | 71 | 180,80 | 179,43 | 114 | 290,30 | 288,93 |

| 29 | 73,85 | 72,48 | 72 | 183,35 | 181,97 | 115 | 292,85 | 291,47 |

| 30 | 76,39 | 75,02 | 73 | 185,89 | 184,52 | 116 | 295,39 | 294,02 |

| 31 | 78,94 | 77,57 | 74 | 188,44 | 187,07 | 117 | 297,94 | 296,57 |

| 32 | 81,49 | 80,12 | 75 | 190,99 | 189,61 | 118 | 300,48 | 299,11 |

| 33 | 84,03 | 82,66 | 76 | 193,53 | 192,16 | 119 | 303,03 | 301,66 |

| 34 | 86,58 | 85,21 | 77 | 196,08 | 194,71 | 120 | 305,58 | 304,21 |

| 35 | 89,13 | 87,75 | 78 | 198,63 | 197,25 | 121 | 308,12 | 306,75 |

| 36 | 91,67 | 90,30 | 79 | 201,17 | 199,80 | 122 | 310,67 | 309,30 |

| 37 | 94,22 | 92,85 | 80 | 203,72 | 202,35 | 123 | 313,22 | 311,84 |

| 38 | 96,77 | 95,39 | 81 | 206,26 | 204,89 | 124 | 315,76 | 314,39 |

| 39 | 99,31 | 97,94 | 82 | 208,81 | 207,44 | 125 | 318,31 | 316,94 |

| 40 | 101,86 | 100,49 | 83 | 211,36 | 209,99 | 126 | 320,86 | 319,48 |

| 41 | 104,41 | 103,03 | 84 | 213,90 | 212,53 | 127 | 323,40 | 322,03 |

| 42 | 106,95 | 105,58 | 85 | 216,45 | 215,08 | 128 | 325,95 | 324,58 |

| 43 | 109,50 | 108,13 | 86 | 219,00 | 217,63 | 129 | 328,50 | 327,12 |

| 44 | 112,05 | 110,67 | 87 | 221,54 | 220,17 | 130 | 331,04 | 329,67 |

| 45 | 114,59 | 113,22 | 88 | 224,09 | 222,72 | 131 | 333,59 | 332,22 |

| 46 | 117,14 | 115,77 | 89 | 226,64 | 225,26 | 132 | 336,14 | 334,76 |

| 47 | 119,68 | 118,31 | 90 | 229,18 | 227,81 | 133 | 338,68 | 337,31 |

| 48 | 122,23 | 120,86 | 91 | 231,73 | 230,36 | 134 | 341,23 | 339,86 |

| 49 | 124,78 | 123,41 | 92 | 234,28 | 232,90 | 135 | 343,77 | 342,40 |

| 50 | 127,32 | 125,95 | 93 | 236,82 | 235,45 | 136 | 346,32 | 344,95 |

| 51 | 129,87 | 128,50 | 94 | 239,37 | 238,00 | 137 | 348,87 | 347,50 |

| 52 | 132,42 | 131,04 | 95 | 241,92 | 240,54 | 138 | 351,41 | 350,04 |

| 53 | 134,96 | 133,59 | 86 | 244,46 | 243,09 | 139 | 353,96 | 352,59 |

| 54 | 137,51 | 136,14 | 67 | 247,01 | 245,64 | 140 | 356,51 | 355,14 |

| 55 | 140,06 | 138,68 | 98 | 249,56 | 248,18 | 141 | 359,05 | 357,68 |

| 56 | 142,60 | 141,23 | 99 | 252,10 | 250,73 | 142 | 361,60 | 360,23 |

| 57 | 145,15 | 143,78 | 100 | 254,65 | 253,28 | 143 | 364,15 | 362,77 |

| 58 | 147,70 | 146,32 | 101 | 257,19 | 255,82 | 144 | 366,69 | 365,32 |

| 59 | 150,24 | 148,87 | 102 | 259,74 | 258,37 | |||

| 60 | 152,79 | 151,42 | 103 | 262,29 | 260,92 |

| Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) |

| 28 | 124,78 | 121,98 | 70 | 311,94 | 309,15 | 112 | 499,11 | 496,32 |

| 29 | 129,23 | 126,44 | 71 | 316,40 | 313,61 | 113 | 503,57 | 500,77 |

| 30 | 133,69 | 130,90 | 72 | 320,86 | 318,06 | 114 | 508,02 | 505,23 |

| 31 | 138,15 | 135,35 | 73 | 325,31 | 322,52 | 115 | 512,48 | 509,68 |

| 32 | 142,60 | 139,81 | 74 | 329,77 | 326,98 | 116 | 516,94 | 514,14 |

| 33 | 147,06 | 144,27 | 75 | 334,23 | 331,43 | 117 | 521,39 | 518,60 |

| 34 | 151,52 | 148,72 | 76 | 338,68 | 335,89 | 118 | 525,85 | 523,05 |

| 35 | 155,97 | 153,18 | 77 | 343,14 | 340,34 | 119 | 530,30 | 527,51 |

| 36 | 160,43 | 157,63 | 78 | 347,59 | 344,80 | 120 | 534,76 | 531,97 |

| 37 | 164,88 | 162,09 | 79 | 352,05 | 349,26 | 121 | 539,22 | 536,42 |

| 38 | 169,34 | 166,55 | 80 | 356,51 | 353,71 | 122 | 543,67 | 540,88 |

| 39 | 173,80 | 171,00 | 81 | 360,96 | 358,17 | 123 | 548,13 | 545,34 |

| 40 | 178,25 | 175,46 | 82 | 365,42 | 362,63 | 124 | 552,59 | 549,79 |

| 41 | 182,71 | 179,92 | 83 | 369,88 | 367,08 | 125 | 557,04 | 554,25 |

| 42 | 197,17 | 184,37 | 84 | 374,33 | 371,54 | 126 | 561,50 | 558,70 |

| 43 | 191,62 | 188,83 | 85 | 378,79 | 375,99 | 127 | 565,96 | 563,16 |

| 44 | 196,08 | 193,28 | 86 | 383,25 | 380,45 | 128 | 570,41 | 567,62 |

| 45 | 200,54 | 197,74 | 87 | 387,70 | 384,91 | 129 | 574,87 | 572,07 |

| 46 | 204,99 | 202,20 | 88 | 392,16 | 389,36 | 130 | 579,32 | 576,53 |

| 47 | 209,45 | 206,65 | 89 | 396,61 | 393,82 | 131 | 583,78 | 580,99 |

| 48 | 213,90 | 211,11 | 90 | 401,07 | 398,28 | 132 | 588,24 | 585,44 |

| 49 | 218,36 | 215,57 | 91 | 405,53 | 402,73 | 133 | 592,69 | 589,90 |

| 50 | 222,82 | 220,02 | 92 | 409,98 | 407,19 | 134 | 597,15 | 594,36 |

| 51 | 227,27 | 224,48 | 93 | 414,44 | 411,65 | 135 | 601,61 | 598,81 |

| 52 | 231,73 | 228,94 | 94 | 418,90 | 416,10 | 136 | 606,06 | 603,27 |

| 53 | 236,19 | 233,39 | 95 | 423,35 | 420,56 | 137 | 610,52 | 607,72 |

| 54 | 240,64 | 237,85 | 96 | 427,81 | 425,01 | 138 | 614,97 | 612,18 |

| 55 | 245,10 | 242,30 | 97 | 432,26 | 429,47 | 139 | 619,43 | 616,64 |

| 56 | 249,56 | 246,76 | 98 | 436,72 | 433,93 | 140 | 623,89 | 621,09 |

| 57 | 254,01 | 251,22 | 99 | 441,18 | 438,38 | 141 | 628,34 | 625,55 |

| 58 | 258,47 | 255,67 | 100 | 445,63 | 442,84 | 142 | 632,80 | 630,01 |

| 59 | 262,92 | 260,13 | 101 | 450,09 | 447,30 | 143 | 637,26 | 634,46 |

| 60 | 267,38 | 264,59 | 102 | 454,55 | 451,75 | 144 | 641,71 | 638,92 |

| 61 | 271,84 | 269,04 | 103 | 459,00 | 456,21 | 145 | 646,17 | 643,38 |

| 62 | 276,29 | 273,50 | 104 | 463,46 | 460,67 | 146 | 650,63 | 647,83 |

| 63 | 280,75 | 277,96 | 105 | 467,92 | 465,12 | 147 | 655,08 | 652,29 |

| 64 | 285,21 | 282,41 | 106 | 472,37 | 469,58 | 148 | 659,54 | 656,74 |

| 65 | 289,66 | 286,87 | 107 | 476,83 | 474,03 | 149 | 663,99 | 661,20 |

| 66 | 294,12 | 291,32 | 108 | 481,28 | 478,49 | 150 | 668,45 | 665,66 |

| 67 | 298,57 | 295,78 | 109 | 485,74 | 482,95 | |||

| 68 | 303,03 | 300,24 | 110 | 490,20 | 487,40 | |||

| 69 | 307,49 | 304,69 | 111 | 494,65 | 491,86 |

| Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) | |

| 10 | 6,37 | 5,86 | 55 | 35,01 | 34,51 | |

| 11 | 7,00 | 6,49 | 56 | 35,65 | 35,14 | |

| 12 | 7,64 | 7,13 | 57 | 36,29 | 35,78 | |

| 13 | 8,28 | 7,77 | 58 | 36,92 | 36,42 | |

| 14 | 8,91 | 8,40 | 59 | 37,56 | 37,05 | |

| 15 | 9,55 | 9,04 | 60 | 38,2 | 37,69 | |

| 16 | 10,19 | 9,68 | 61 | 38,83 | 38,33 | |

| 17 | 10,82 | 10,31 | 62 | 39,47 | 38,96 | |

| 18 | 11,46 | 10,95 | 63 | 40,11 | 39,6 | |

| 19 | 12,10 | 11,59 | 64 | 40,74 | 40,24 | |

| 20 | 12,73 | 12,22 | 65 | 41,38 | 40,87 | |

| 21 | 13,37 | 12,86 | 66 | 42,02 | 41,51 | |

| 22 | 14,01 | 13,50 | 67 | 42,65 | 42,15 | |

| 23 | 14,64 | 14,13 | 68 | 43,29 | 42,78 | |

| 24 | 15,28 | 14,77 | 69 | 43,93 | 43,42 | |

| 25 | 15,92 | 15,41 | 70 | 44,56 | 44,06 | |

| 26 | 16,55 | 16,04 | 71 | 45,20 | 44,69 | |

| 27 | 17,19 | 16,68 | 72 | 45,84 | 45,33 | |

| 28 | 17,83 | 17,32 | 73 | 46,47 | 45,97 | |

| 29 | 18,46 | 17,95 | 74 | 47,11 | 46,6 | |

| 30 | 19,10 | 18,59 | 75 | 47,75 | 47,24 | |

| 31 | 19,74 | 19,23 | 76 | 48,38 | 47,88 | |

| 32 | 20,37 | 19,86 | 77 | 49,02 | 48,51 | |

| 33 | 21,01 | 20,50 | 78 | 49,66 | 49,15 | |

| 34 | 21,65 | 21,14 | 79 | 50,29 | 49,78 | |

| 35 | 22,28 | 21,77 | 80 | 50,93 | 50,42 | |

| 36 | 22,92 | 22,41 | 71 | 51,57 | 51,06 | |

| 37 | 23,55 | 23,05 | 82 | 52,2 | 51,69 | |

| 38 | 24,19 | 23,68 | 83 | 52,84 | 52,33 | |

| 39 | 24,83 | 24,32 | 84 | 53,48 | 52,97 | |

| 40 | 25,46 | 24,96 | 85 | 54,11 | 53,6 | |

| 41 | 26,10 | 25,59 | 86 | 54,75 | 54,24 | |

| 42 | 26,74 | 26,23 | 87 | 55,39 | 54,88 | |

| 43 | 27,37 | 26,87 | 88 | 56,02 | 55,51 | |

| 44 | 28,01 | 27,50 | 89 | 56,66 | 56,15 | |

| 45 | 28,65 | 28,14 | 90 | 57,30 | 56,79 | |

| 46 | 29,28 | 28,78 | ||||

| 47 | 29,92 | 29,41 | ||||

| 48 | 30,56 | 30,05 | ||||

| 49 | 31,19 | 30,69 | ||||

| 50 | 31,83 | 31,32 | ||||

| 51 | 32,47 | 31,96 | ||||

| 52 | 33,10 | 32,60 | ||||

| 53 | 33,74 | 33,23 | ||||

| 54 | 34,39 | 33,87 |

| Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) |

| 10 | 9,55 | 8,78 | 55 | 52,52 | 51,75 |

| 11 | 10,50 | 9,74 | 56 | 53,48 | 52,71 |

| 12 | 11,46 | 10,69 | 57 | 54,43 | 53,66 |

| 13 | 12,41 | 11,65 | 58 | 55,39 | 54,62 |

| 14 | 13,37 | 12,60 | 59 | 56,34 | 55,57 |

| 15 | 14,32 | 13,56 | 60 | 57,30 | 56,53 |

| 16 | 15,28 | 14,51 | 61 | 58,25 | 57,48 |

| 17 | 16,23 | 15,47 | 62 | 59,21 | 58,44 |

| 18 | 17,19 | 16,42 | 63 | 60,16 | 59,39 |

| 19 | 18,14 | 17,38 | 64 | 61,12 | 60,35 |

| 20 | 19,10 | 18,33 | 65 | 62,07 | 61,30 |

| 21 | 20,05 | 19,29 | 66 | 63,03 | 62,26 |

| 22 | 21,01 | 20,24 | 67 | 63,98 | 63,21 |

| 23 | 21,96 | 21,20 | 68 | 64,94 | 64,17 |

| 24 | 22,92 | 22,15 | 69 | 65,89 | 65,12 |

| 25 | 23,87 | 23,11 | 70 | 66,85 | 66,08 |

| 26 | 24,83 | 24,06 | 71 | 67,80 | 67,03 |

| 27 | 25,78 | 25,02 | 72 | 68,78 | 67,99 |

| 28 | 26,74 | 25,97 | 73 | 69,71 | 68,94 |

| 29 | 27,69 | 26,92 | 74 | 70,66 | 69,90 |

| 30 | 28,65 | 27,88 | 75 | 71,62 | 70,85 |

| 31 | 29,60 | 28,83 | 76 | 72,57 | 71,81 |

| 32 | 30,56 | 29,79 | 77 | 73,53 | 72,76 |

| 33 | 31,51 | 30,74 | 78 | 74,48 | 73,72 |

| 34 | 32,47 | 31,70 | 79 | 75,44 | 74,67 |

| 35 | 33,42 | 32,65 | 80 | 76,39 | 75,63 |

| 36 | 34,38 | 33,61 | 71 | 77,35 | 76,58 |

| 37 | 35,33 | 34,56 | 82 | 78,30 | 77,54 |

| 38 | 36,29 | 35,52 | 83 | 79,26 | 78,49 |

| 39 | 37,24 | 36,47 | 84 | 80,21 | 79,45 |

| 40 | 38,20 | 37,43 | 85 | 81,17 | 80,40 |

| 41 | 39,15 | 38,38 | 86 | 82,12 | 81,36 |

| 42 | 40,11 | 39,34 | 87 | 83,08 | 82,31 |

| 43 | 41,06 | 40,29 | 88 | 84,03 | 83,27 |

| 44 | 42,02 | 41,25 | 89 | 84,99 | 84,22 |

| 45 | 42,97 | 42,20 | 90 | 85,94 | 85,18 |

| 46 | 43,93 | 43,16 | |||

| 47 | 44,88 | 44,11 | |||

| 48 | 45,84 | 45,07 | |||

| 49 | 46,79 | 46,02 | |||

| 50 | 47,75 | 46,98 | |||

| 51 | 48,70 | 47,93 | |||

| 52 | 49,66 | 48,89 | |||

| 53 | 50,61 | 49,84 | |||

| 54 | 51,57 | 50,80 |

| Teeth no. | Effective Ø (mm) | Outer Ø (mm) | Teeth no. | Effective Ø (mm) | Outer Ø (mm) |

| 10 | 15,92 | 14,96 | 55 | 87,54 | 86,58 |

| 11 | 17,51 | 16,55 | 56 | 89,13 | 88,17 |

| 12 | 19,10 | 18,14 | 57 | 90,72 | 89,76 |

| 13 | 20,69 | 19,73 | 58 | 92,31 | 91,35 |

| 14 | 22,28 | 21,32 | 59 | 93,90 | 92,94 |

| 15 | 23,87 | 22,91 | 60 | 95,49 | 94,53 |

| 16 | 25,46 | 24,50 | 61 | 97,08 | 96,12 |

| 17 | 27,06 | 26,10 | 62 | 98,68 | 97,72 |

| 18 | 28,65 | 27,69 | 63 | 100,27 | 99,31 |

| 19 | 30,24 | 29,28 | 64 | 101,86 | 100,90 |

| 20 | 31,83 | 30,87 | 65 | 103,45 | 102,49 |

| 21 | 33,42 | 32,47 | 66 | 105,04 | 104,08 |

| 22 | 35,01 | 34,05 | 67 | 106,63 | 105,67 |

| 23 | 36,61 | 35,65 | 68 | 108,23 | 107,27 |

| 24 | 38,20 | 37,24 | 69 | 109,82 | 108,86 |

| 25 | 39,79 | 38,83 | 70 | 111,41 | 110,45 |

| 26 | 41,38 | 40,42 | 71 | 113,00 | 112,04 |

| 27 | 42,97 | 42,01 | 72 | 114,59 | 113,63 |

| 28 | 44,56 | 43,60 | 73 | 116,18 | 115,22 |

| 29 | 46,15 | 45,19 | 74 | 117,77 | 116,81 |

| 30 | 47,75 | 46,79 | 75 | 119,37 | 118,41 |

| 31 | 49,34 | 46,38 | 76 | 120,96 | 120,00 |

| 32 | 50,93 | 49,97 | 77 | 122,55 | 121,59 |

| 33 | 52,52 | 51,56 | 78 | 124,14 | 123,18 |

| 34 | 54,11 | 53,15 | 79 | 125,73 | 124,77 |

| 35 | 55,70 | 54,74 | 80 | 127,32 | 126,36 |

| 36 | 57,30 | 56,34 | 71 | 128,92 | 127,96 |

| 37 | 58,89 | 57,93 | 82 | 130,51 | 129,55 |

| 38 | 60,48 | 59,52 | 83 | 132,10 | 131,14 |

| 39 | 62,07 | 61,11 | 84 | 133,69 | 132,73 |

| 40 | 63,66 | 62,70 | 85 | 135,28 | 134,32 |

| 41 | 65,25 | 64,29 | 86 | 136,87 | 135,91 |

| 42 | 66,85 | 65,89 | 87 | 138,46 | 137,50 |

| 43 | 68,44 | 67,48 | 88 | 140,06 | 139,10 |

| 44 | 70,03 | 69,07 | 89 | 141,65 | 140,69 |

| 45 | 71,62 | 70,66 | 90 | 143,24 | 142,28 |

| 46 | 73,21 | 72,25 | |||

| 47 | 74,80 | 73,84 | |||

| 48 | 76,39 | 75,43 | |||

| 49 | 77,99 | 77,03 | |||

| 50 | 79,58 | 78,62 | |||

| 51 | 81,17 | 80,21 | |||

| 52 | 82,76 | 81,80 | |||

| 53 | 84,35 | 83,39 | |||

| 54 | 85,94 | 84,98 |

| Tolerances of outer diameter | ||||

| Outer diameter | Permitted tolerance |

Permitted rotational deviation |

Rough turning Oversize (da) + |

|

| mm from | mm to | mm | mm | mm |

| 0 | 50 | +0,05 | 0,04 | 1 |

| 51 | 100 | +0,08 | 0,05 | |

| 101 | 150 | +0,10 | 0,07 | |

| 151 | 200 | +0,12 | 0,10 | |

| 201 | 300 | +0,15 | 0,12 | |

| 301 | 500 | +0,18 | +0,03 pro 100mm Outer diameter |

|

| 501 | ... | +0,20 | ||

| Axial run-out tolerance | |

| Outer diameter | Permitted rotational deviation |

| mm | mm |

| bis 101,60 | 0.1 |

| über 101,60 bis 250,00 |

0,1 +0,1mm pro 100mm Outer diameter |

| über 251,00 | 0,25 +0,05mm pro 100mm Outer diameter |

| Surface Rz | |

| Pitch | permitted peak-to-valley roughness Rz |

| 8 mm | Rz < 16 |

| 14 mm | Rz < 25 |

The Correct Mounting

Pulleys and, of course, belts themselves always have to be mounted with the correct alignment. This means that belts cannot be bent or buckled in any way, which could lead to a drop below the minimum permissible pulley diameter. That corresponds to approximately 50 mm for belts with a pitch of 8 mm and about 125 mm for those belts with a 14 mm pitch. Imbalanced drives cause a variety of belt tension problems and edge stresses and are also responsible for extreme lateral movement, the undesired wobble. All this leads to increased operating noise and more wear and tear on the belt. Therefore the parallelism error of the pulleys should only amount to a maximum of 0.5% of the centre distance. Angle accuracy is to be maintained by keeping misalignment down to 0.25° at the very most.

Pre-Tensioning The Belt Correctly

Firstly the belt always has to be tightened in line with the calculated pre-tensioning force and checked after a running-in period of about 5 minutes. The belt is then to be retightened according to the relevant value, should it have shifted or altered its position in any way. Finally after a further 8 hours of operating, the belt is to be once again inspected and, if necessary, tightened to comply with the required value that has already been calculated.

Causes of failure and corrective measures can be found in the following document:

| Belt length mm |

Minimal adjustment for installation |

Required adjustment range for tightening |

|

| 8M | 14M | 8M, 14M | |

| smaller than 1525 | 34,5 mm | 59,5 mm | 2,5 mm |

| 1525 - 3050 | 37,0 mm | 62,0 mm | 5,0 mm |

| greater than 3050 | 39,5 mm | 64,5 mm | 7,5 mm |