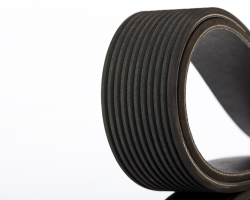

Multirib Belts

Such belts are mainly used at high speeds and for large transmission ratios. These belts run on small pulley diameters and, as a result of their larger surface, they transmit a considerably higher degree of performance than V-belts of the same size.

Advantages

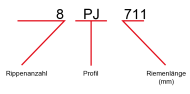

This belt can be obtained with the profile shapes J / K / L and M.

- Partially oil resistant

- These belts can be operated within a temperature range of -30°C up to +80°C

- They are electrically conductive in accordance with ISO 1813

- They are suitable for tropical conditions, are ageing resistant and also ozone resistant

- Such belts can be used with inner and outer idler pulleys

- And they are particularly smooth-running

| Effektiver Umfang (mm) |

Größencode | |

| 356 | 140 | |

| 381 | 150 | |

| 406 | 160 | |

| 432 | 170 | |

| 457 | 180 | |

| 483 | 190 | |

| 508 | 200 | |

| 533 | 210 | |

| 559 | 220 | |

| 584 | 230 | |

| 610 | 240 | |

| 630 * | 248 | |

| 660 | 260 | |

| 686 | 270 | |

| 711 | 280 | |

| 723 * | 285 | |

| 737 | 290 | |

| 762 | 300 | |

| 787 | 310 | |

| 813 | 320 | |

| 838 | 330 | |

| 864 | 340 | |

| 889 | 350 | |

| 914 | 360 | |

| 940 * | 370 | |

| 965 | 380 | |

| 991 | 390 | |

| 1016 | 400 | |

| 1031 * | 406 | |

| 1054 | 415 | |

| 1092 | 430 | |

| 1105 | 435 | |

| 1128 * | 444 | |

| 1143 | 450 | |

| 1151 | 453 | |

| 1168 | 460 | |

| 1194 | 470 | |

| 1200 | 472 | |

| 1208 * | 476 | |

| 1219 | 480 | |

| 1245 | 490 | |

| 1270 | 500 | |

| 1287 * | 507 | |

| 1295 | 510 | |

| 1321 | 520 | |

| 1333 | 525 | |

| 1346 | 530 | |

| 1372 | 540 | |

| 1397 | 550 | |

| 1422 | 560 | |

| 1439 * | 567 | |

| 1461 | 575 | |

| 1473 | 580 | |

| 1549 | 610 | |

| 1600 | 630 | |

| 1626 | 640 | |

| 1651 | 650 | |

| 1661 * | 654 | |

| 1702 | 670 | |

| 1753 | 690 | |

| 1778 | 700 | |

| 1854 | 730 | |

| 1915 * | 754 | |

| 1930 | 760 | |

| 1956 | 770 | |

| 1981 | 780 | |

| 2019 | 795 | |

| 2083 | 820 | |

| 2210 | 870 | |

| 2286 | 900 | |

| 2337 | 920 | |

| 2489 | 980 |

| Effektiver Umfang (mm) |

Größencode | |

| PK | 630 | 248 |

| PK | 635 * | 250 |

| PK | 648 * | 255 |

| PK | 698 * | 275 |

| PK | 730 | 287 |

| PK | 775 | 305 |

| PK | 800 | 315 |

| PK | 813 | 320 |

| PK | 830 | 327 |

| PK | 865 * | 341 |

| PK | 870 * | 343 |

| PK | 885 | 348 |

| PK | 925 | 364 |

| PK | 950 * | 374 |

| PK | 960 | 378 |

| PK | 970 * | 382 |

| PK | 1010 * | 398 |

| PK | 1015 * | 400 |

| PK | 1035 | 407 |

| PK | 1060 * | 417 |

| PK | 1080 * | 425 |

| PK | 1132 | 446 |

| PK | 1145 * | 451 |

| PK | 1200 | 472 |

| PK | 1207 | 475 |

| PK | 1215 * | 478 |

| PK | 1230 | 484 |

| PK | 1246 | 491 |

| PK | 1280 * | 504 |

| PK | 1298 | 511 |

| PK | 1300 | 512 |

| PK | 1314 * | 517 |

| PK | 1335 * | 526 |

| PK | 1357 * | 534 |

| PK | 1385 | 545 |

| PK | 1400 * | 551 |

| PK | 1420 | 559 |

| PK | 1460 | 575 |

| PK | 1475 * | 581 |

| PK | 1481 | 583 |

| PK | 630 | 248 |

| PK | 635 * | 250 |

| PK | 648 * | 255 |

| PK | 698 * | 275 |

| PK | 730 | 287 |

| PK | 775 | 305 |

| PK | 800 | 315 |

| PK | 813 | 320 |

| PK | 830 | 327 |

| PK | 865 * | 341 |

| PK | 870 * | 343 |

| PK | 885 | 348 |

| PK | 925 | 364 |

| PK | 950 * | 374 |

| PK | 960 | 378 |

| PK | 970 * | 382 |

| PK | 1010 * | 398 |

| PK | 1015 * | 400 |

| PK | 1035 | 407 |

| PK | 1060 * | 417 |

| PK | 1080 * | 425 |

| PK | 1132 | 446 |

| PK | 1145 * | 451 |

| PK | 1200 | 472 |

| PK | 1207 | 475 |

| PK | 1215 * | 478 |

| PK | 1230 | 484 |

| PK | 1246 | 491 |

| PK | 1280 * | 504 |

| PK | 1298 | 511 |

| PK | 1300 | 512 |

| PK | 1314 * | 517 |

| PK | 1335 * | 526 |

| PK | 1357 * | 534 |

| PK | 1385 | 545 |

| PK | 1400 * | 551 |

| PK | 1420 | 559 |

| PK | 1460 | 575 |

| PK | 1475 * | 581 |

| PK | 1481 | 583 |

| Effektiver Umfang (mm) |

Größencode |

| 927 * | 365 |

| 953 | 375 |

| 991 | 390 |

| 1041 | 410 |

| 1074 | 423 |

| 1080 * | 425 |

| 1149 | 452 |

| 1168 | 460 |

| 1194 | 470 |

| 1219 | 480 |

| 1270 | 500 |

| 1295 | 510 |

| 1321 | 520 |

| 1333 | 525 |

| 1346 * | 530 |

| 1372 | 540 |

| 1397 | 550 |

| 1422 | 560 |

| 1435 | 565 |

| 1473 | 580 |

| 1499 | 590 |

| 1562 | 615 |

| 1613 | 635 |

| 1651 | 650 |

| 1664 | 655 |

| 1715 | 675 |

| 1765 | 695 |

| 1803 | 710 |

| 1841 | 725 |

| 1943 | 765 |

| 1956 | 770 |

| 1981 | 780 |

| 2019 | 795 |

| 2070 | 815 |

| 2095 * | 825 |

| 2134 | 840 |

| 2195 | 864 |

| 2235 | 880 |

| 2324 | 915 |

| 2362 | 930 |

| 2477 | 975 |

| 2515 | 990 |

| 2565 | 1010 |

| 2705 | 1065 |

| 2743 | 1080 |

| 2845 | 1120 |

| 2895 | 1140 |

| 2921 | 1150 |

| 2997 | 1180 |

| 3085 | 1215 |

| 3124 | 1230 |

| 3289 | 1295 |

| 3327 | 1310 |

| 3492 | 1375 |

| 3696 | 1455 |

| 4051 | 1595 |

| 4191 | 1650 |

| 4318 * | 1700 |

| 4470 | 1760 |

| 4622 | 1820 |

| 5029 | 1980 |

| 5200 * | 2047 |

| 5385 | 2120 |

| 6096 | 2400 |

| Effektiver Umfang (mm) |

Größencode |

| 2134 * | 840 |

| 2286 | 900 |

| 2388 * | 940 |

| 2515 | 990 |

| 2693 | 1060 |

| 2832 | 1115 |

| 2921 | 1150 |

| 3010 | 1185 |

| 3124 | 1230 |

| 3327 | 1310 |

| 3429 * | 1350 |

| 3531 | 1390 |

| 3648 * | 1436 |

| 3734 * | 1470 |

| 3937 * | 1550 |

| 4089 | 1610 |

| 4191 * | 1650 |

| 4470 | 1760 |

| 4648 * | 1830 |

| 5029 | 1980 |

| 5410 * | 2130 |

| 5600 * | 2205 |

| 6121 * | 2410 |

| 6700 * | 2638 |

| 6883 * | 2710 |

| 7645 * | 3010 |

| 8408 * | 3310 |

| 9169 * | 3610 |

| 9931 * | 3910 |

| 10350 * | 4075 |

| 10693 * | 4210 |

| 12217 * | 4810 |

| 13741 * | 5410 |

| 15266 * | 6010 |

| 16764 * | 6600 |

Alongside our wide standard range of this product, we also craft in our ateliers high-precision drawing parts and customised special pulley washers. With all our products we offer a comprehensive service ranging from the manufacturing of mechanical processing parts and gearing components right up to the mounting of finished systems and assembly units.

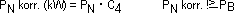

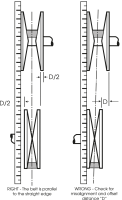

Pre-Tensioning The Belt Correctly

Firstly the belt always has to be tightened in line with the calculated pre-tensioning force and checked after a running-in period of about 5 minutes. The belt is then to be retightened according to the relevant value, should it have shifted or altered its position in any way. Finally after a further 8 hours of operating, the belt is to be once again inspected and, if necessary, tightened to comply with the required value that has already been calculated.

Causes of failure and corrective measures can be found in the following document:

Troubleshooting for power transmission products

| Belt length mm |

minimal adjustment for installation (mm) |

Required adjustemnt range for tightening |

||

| J | L | |||

| up to 508 | 10,16 | 7,62 | ||

| up to 508 - 1016 | 12,70 | 12,70 | ||

| up to 1016 - 1524 | 15,24 | 22,86 | 17,78 | |

| up to 1524 - 2032 | 15,24 | 22,86 | 22,86 | |

| up to 2032 - 2540 | 17,78 | 25,40 | 27,94 | |

| up to 2540 - 3048 | 20,32 | 27,94 | 33,02 | |

| up to 3048 - 4064 | 30,48 | 43,18 | ||

| up to 4064 - 5080 | 33,02 | 55,88 | ||

| up to 5080 - 6096 | 35,56 | 66,04 | ||

| up to 6096 - 7620 | 83,82 | |||

| up to 7620 - 9144 | 99,06 | |||

| up to 9144 - 10668 | 116,84 | |||

| up to 10668 - 12192 | 132,08 | |||

| up to 12192 - 13716 | 147,32 | |||

| up to 13716 - 15240 | 165,10 | |||