Maxstar Power (HA-HB)

The banded Maxstar Power was developed to accommodate the needs of agricultural machines such as corn choppers and combine harvesters.

Properties

The Maxstar Power is constructed out of a chloroprene rubber compound and is available either with aramid tensile cords (HA K/HB K) or with polyester tensile cords (HA - HB).

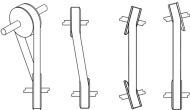

The Maxstar Power also comes as a multi-belt – this Maxstar Power Multi-Belt (banded) is produced with two or more V-belts, which are linked by means of a coating on the outer edge. Such a belt can be used on every standard pulley wheel. This outer coating never comes into contact with the pulley wheel with the result that there is no risk of any jamming whatsoever.

Examples of Applications

In the majority of applications, requirements can be met by using V-belts. However, under certain conditions, vibration or impact can lead to problems in the drive belt. There is then the danger of pulley wheels, i.e. sheaves, dislodging. Such an action could result in the belt becoming damaged or even totally ruined. Possible reasons for this are as follows:

- Load vibration which can occasionally arise on the drive end or on the output side

- Intensive impact stress

- Long centre distances

As a result of such factors, belt vibration can occur both in a longitudinal and also in a transverse direction. In such cases standard wedge or V-belts could be easily dislodged or even totally ruined. Banded multi-wedge belts are therefore recommended for such situations because they succeed in considerably and visibly minimising vibration. The logical result is then that the application enjoys a significantly longer service life.

| Available belt pitches | HA | HB | HA K | HB K | |

| Belt type | mantled | ||||

| Doouble V-Belt available? | yes | yes | yes | yes | |

| Tolerance according to: | MBL | ||||

| Belt material | Rubber | Chloropren | |||

| Tensile member | Polyester | Aramid | |||

| Coating | Cotton-Polyester mixture (special completion) |

||||

| electrical conductivity | yes | ||||

| Temperature-range | -30 ~ +90 | ||||

| Wear resistance | normal | ||||

| Heat resistance | normal | ||||

| max. belt speed | (m/s) | 40 | |||

| Weight | (kg/m) | 0.12 | 0.20 | 0.12 | 0.2 |

| available lengths | on request | ||||

| Maxstar Power (HA-HB) | |||||

| available belt pitches | HA | HB | HA K | HB K | |

| available lengths | on request | ||||

Alongside our wide standard range of this product, we also craft in our ateliers high-precision drawing parts and customised special pulley washers. With all our products we offer a comprehensive service ranging from the manufacturing of mechanical processing parts and gearing components right up to the mounting of finished systems and assembly units.

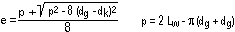

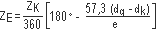

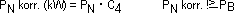

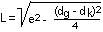

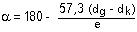

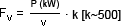

Pre-Tensioning The Belt Correctly

Firstly the belt always has to be tightened in line with the calculated pre-tensioning force and checked after a running-in period of about 5 minutes. The belt is then to be retightened according to the relevant value, should it have shifted or altered its position in any way. Finally after a further 8 hours of operating, the belt is to be once again inspected and, if necessary, tightened to comply with the required value that has already been calculated.

Causes of failure and corrective measures can be found in the following document:

Troubleshooting for power transmission products