Polymax Belts

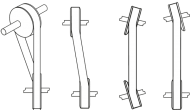

The MITSUBOSHI Polymax is a wide angle belt, constructed out of polyurethane and having an angle of ca. 60°. It is the preferred belt for high speed applications where vibration is to be kept to an absolute minimum. This belt is weather-proof and is available as a single or as a multi belt.

This is a wide angle belt with an angle of approximately 60 degrees. It marries together the following hallmarks to produce a superior modus operandi:

- Top speed power transmission with minimal vibration

- Suitable for compactly-designed applications

- Reduces costs

- Maintenance-free

- Stretch resistant

- Excellent water resistance

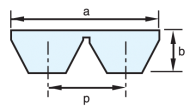

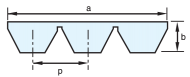

| Number of rips | 2 | 3 | ||||

| Typ | 5M | 7M | 11M | 5M | 7M | 11M |

| a | 9.8 | 15.6 | 24.4 | 15.1 | 24.1 | 37.6 |

| b | 3.5 | 5.3 | 7.0 | 3.5 | 5.3 | 7.0 |

| P | 5.3 | 8.5 | 13.2 | 5.3 | 8.5 | 13.2 |

| Measurement in mm | ||||||

| Belt material | Polyurethane | |

| Belt type | Poly-Max | |

| Tolerance according to | JIS-Norm | |

| Tensile member | Polyester | |

| Mantled | no | |

| electrical conductivity | on request | |

| according to norm | MBL | |

| Temperature range | -40°C - + 80°C | |

| Wear resistance | good | |

| reenforced | no | |

| max. speed | 40 m/s | |

| Multi V-Belt available? | yes |

| Size Code | Size Code | |||

| 3M | 180 | 3M | 375 | |

| 3M | 185 | 3M | 387 | |

| 3M | 190 | 3M | 400 | |

| 3M | 195 | 3M | 412 | |

| 3M | 200 | 3M | 425 | |

| 3M | 206 | 3M | 437 | |

| 3M | 212 | 3M | 450 | |

| 3M | 218 | 3M | 462 | |

| 3M | 224 | 3M | 475 | |

| 3M | 230 | 3M | 487 | |

| 3M | 236 | 3M | 500 | |

| 3M | 243 | 3M | 515 | |

| 3M | 250 | 3M | 530 | |

| 3M | 258 | 3M | 545 | |

| 3M | 265 | 3M | 560 | |

| 3M | 272 | 3M | 580 | |

| 3M | 280 | 3M | 600 | |

| 3M | 290 | 3M | 615 | |

| 3M | 300 | 3M | 630 | |

| 3M | 307 | 3M | 670 | |

| 3M | 315 | 3M | 690 | |

| 3M | 325 | 3M | 710 | |

| 3M | 335 | 3M | 730 | |

| 3M | 345 | 3M | 750 | |

| 3M | 355 | |||

| 3M | 365 | |||

| Size Code | Size Code | ||

| 5M | 280 | 5M | 690 |

| 5M | 290 | 5M | 710 |

| 5M | 300 | 5M | 730 |

| 5M | 307 | 5M | 750 |

| 5M | 315 | 5M | 775 |

| 5M | 325 | 5M | 800 |

| 5M | 335 | 5M | 805 |

| 5M | 345 | 5M | 825 |

| 5M | 355 | 5M | 850 |

| 5M | 365 | 5M | 875 |

| 5M | 375 | 5M | 900 |

| 5M | 387 | 5M | 925 |

| 5M | 400 | 5M | 950 |

| 5M | 412 | 5M | 975 |

| 5M | 425 | 5M | 1000 |

| 5M | 437 | 5M | 1030 |

| 5M | 450 | 5M | 1060 |

| 5M | 462 | 5M | 1090 |

| 5M | 475 | 5M | 1120 |

| 5M | 487 | 5M | 1150 |

| 5M | 500 | 5M | 1180 |

| 5M | 515 | 5M | 1220 |

| 5M | 530 | 5M | 1250 |

| 5M | 545 | 5M | 1280 |

| 5M | 560 | 5M | 1320 |

| 5M | 580 | 5M | 1360 |

| 5M | 600 | 5M | 1400 |

| 5M | 615 | 5M | 1450 |

| 5M | 630 | 5M | 1500 |

| 5M | 650 | 5M | 1850 |

| 5M | 670 | ||

| also available as Multi-Polymax-Belt | |||

| Size Code | Size Code | ||

| 7M | 500 | 7M | 1090 |

| 7M | 515 | 7M | 1120 |

| 7M | 530 | 7M | 1150 |

| 7M | 545 | 7M | 1180 |

| 7M | 560 | 7M | 1220 |

| 7M | 580 | 7M | 1250 |

| 7M | 600 | 7M | 1280 |

| 7M | 615 | 7M | 1320 |

| 7M | 630 | 7M | 1360 |

| 7M | 650 | 7M | 1400 |

| 7M | 670 | 7M | 1450 |

| 7M | 690 | 7M | 1500 |

| 7M | 710 | 7M | 1550 |

| 7M | 730 | 7M | 1600 |

| 7M | 750 | 7M | 1650 |

| 7M | 775 | 7M | 1700 |

| 7M | 800 | 7M | 1750 |

| 7M | 825 | 7M | 1800 |

| 7M | 850 | 7M | 1850 |

| 7M | 875 | 7M | 1900 |

| 7M | 900 | 7M | 1950 |

| 7M | 925 | 7M | 2000 |

| 7M | 950 | 7M | 2060 |

| 7M | 975 | 7M | 2120 |

| 7M | 1000 | 7M | 2180 |

| 7M | 1030 | 7M | 2240 |

| 7M | 1060 | 7M | 2300 |

| also available as Multi-Polymax-Belt | |||

| Size Code | Size Code | ||

| 11M | 710 | 11M | 1280 |

| 11M | 730 | 11M | 1320 |

| 11M | 750 | 11M | 1360 |

| 11M | 775 | 11M | 1400 |

| 11M | 800 | 11M | 1450 |

| 11M | 825 | 11M | 1500 |

| 11M | 850 | 11M | 1550 |

| 11M | 875 | 11M | 1600 |

| 11M | 900 | 11M | 1650 |

| 11M | 925 | 11M | 1700 |

| 11M | 950 | 11M | 1750 |

| 11M | 975 | 11M | 1800 |

| 11M | 1000 | 11M | 1850 |

| 11M | 1030 | 11M | 1900 |

| 11M | 1060 | 11M | 1950 |

| 11M | 1090 | 11M | 2000 |

| 11M | 1120 | 11M | 2060 |

| 11M | 1150 | 11M | 2120 |

| 11M | 1180 | 11M | 2180 |

| 11M | 1220 | 11M | 2240 |

| 11M | 1250 | 11M | 2300 |

| also available as Multi-Polymax-Belt | |||

Alongside our wide standard range of this product, we also craft in our ateliers high-precision drawing parts and customised special pulley washers. With all our products we offer a comprehensive service ranging from the manufacturing of mechanical processing parts and gearing components right up to the mounting of finished systems and assembly units.

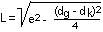

Pre-Tensioning The Belt Correctly

Firstly the belt always has to be tightened in line with the calculated pre-tensioning force and checked after a running-in period of about 5 minutes. The belt is then to be retightened according to the relevant value, should it have shifted or altered its position in any way. Finally after a further 8 hours of operating, the belt is to be once again inspected and, if necessary, tightened to comply with the required value that has already been calculated.

Causes of failure and corrective measures can be found in the following document:

Troubleshooting for power transmission products